You'd think that no single person can design and build a roller coaster, but Ben Katz begs to differ. Equal parts artist and engineer, he is preparing to build a 130-foot roller coaster on the MIT campus, of all places.

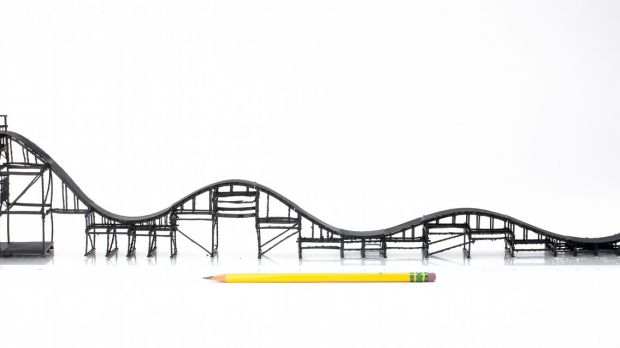

That's not what caught my attention today, though. No, what just cropped up is a 3D printed model of the roller coaster, in 1:60 scale.

It's a stupendously detailed piece of work, thanks to the Formlabs Form 1+ 3D printer stereolithography technology used to create the 15 pieces composing it. The pieces have a layer resolution of 25 microns, hence the high detail level.

The way Katz fused them together also deserves a mention. He took a syringe filled with resin and used a laser pointer to “cure” it while he was applying it to the connection points. Basically, he soldered them together by replicating the abilities of an SLA 3D printer (hardening resin by use of light).

I'm not sure how much time, money and resources Katz will need to actually make the roller coaster on the MIT campus, but he's supposedly quite determined to make it happen. One thing is for sure, it won't happen in 60 hours (that's the time it took to 3D print the 15 pieces, 3-5 hours for each).

14 DAY TRIAL //

14 DAY TRIAL //