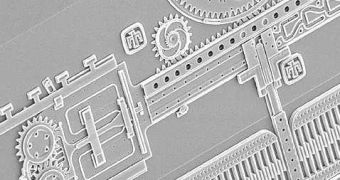

The research conducted at Purdue University has resulted in the creation of tiny wireless sensors which can detect critical bearings that are about to fail. The device which has to endure the harsh temperature conditions inside the jet engine, are the exemplary result of an emerging technology called "micro electromechanical system" or MEMS, devices which combine the electronic and mechanical components at microscopic levels.

Such sensors are extremely useful since they are small enough not to interfere with the general performance of the bearing, functioning at temperatures as high as 300 degrees Celsius. Through it engineers can detect temperature-induced bearing failure, earlier than the previous conventional sensors.

This is extremely crucial when the engine is about to fail, the sensor bringing information about the imminent malfunction before it ever happens, so the operator can have time to shut it down before it fails, avoiding further extensive damage.

The potential applications for these sensors are large, from military aircrafts to helicopters and even conventional cars. Any machine powered by an engine could benefit by installing MEMS sensors to keep track of vital bearings. The technology used to develop the sensors was previously used to create sensors to monitor the bearings inside space communications satellites.

This is a major issue when the bearings support the wheels, which control a multi-million dollar satellite's position. When a bearing failure is considered imminent, the mission controller could switch it off and use the alternative backup solution, but if the bearing fails without any warning, this could cause a sudden gyroscope stop, that could throw the satellite out of the Earth's orbit.

In 2006 the Purdue research team received a grant from the United States Air Force to extend the work to create high temperature jet engine sensors. The current technology allows sensors to work to temperatures up to 210 degrees Celsius, but the military requested a sensor which could work in 300 degrees Celsius temperatures; the team is now concentrating the research mainly on minimizing the size of the components.

They can transmit data about the temperature detected wirelessly, so they don't need batteries to power them, power being provided through a technique of inductive coupling, which uses coils to generate electricity, out of the magnetic field.

This method of telemetry will not only show when the bearings are about to fail, but will probably provide an estimated time of how long it will take before the failure occurs.

14 DAY TRIAL //

14 DAY TRIAL //