The more viscous a material is, the harder it is for a 3D printer to use it. Or, extruders melt plastic well enough, but liquids deform when placed on a flat surface, and materials forced through printing heads are unfortunately subject to this issue.

This is why no 3D printed object ever turns out perfect, when made with Fused Deposition Modeling (FDM).

Now, though, ViscoTec claims to have found a solution for this problem, or at least a way to alleviate it.

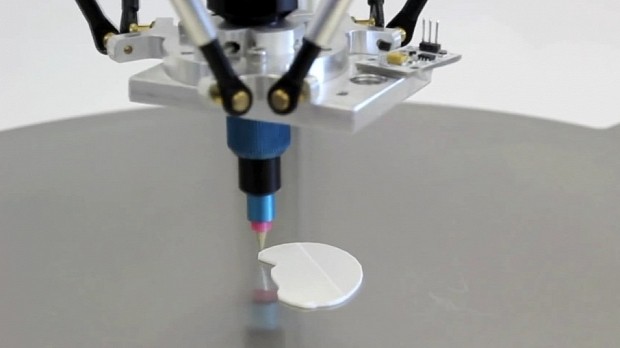

It is a dosing technology that allows 3D printing heads to apply the “endless piston principle” to control the flow of material better than ever.

ViscoTec uses the endless piston principle to rapidly fill bottles of cosmetics and lotions, maintaining and controlling extrusion of materials with a high rate of accuracy.

The videos below explain the technology and even show a demo print using silicone, which is known for its low resolution compared to PLA and ABS.

Bioprinting stands to gain a lot from the newly applied principle, as organic cell solutions, chocolate, pastes, silicones and UV-Curing adhesives all have such a low viscosity that they are beyond the ability of conventional printers to handle.

Unfortunately, while the new print heads are on sale, they are only shipped in bulk, to industrial applications. No word on when consumer printers will see them.

3D printing ViscoTec

3D printing with ViscoTec -1 Silikones, fluids and pastes

14 DAY TRIAL //

14 DAY TRIAL //