Scientists at the University of Minnesota have recently been able to devise cheap ways of manipulating light in peculiar manners, when they have established new techniques to produce very smooth, patterned, thin nanofilms. According to Technology Review, their work could lead to significant improvements in the fields of optical imaging, as well as in the emerging field of optical computing. More efficient solar cells could also become available, the researchers believe.

The main achievement that took place at the UM was the fact that the scientists were able to create metal films that were incredibly smooth. This is an absolute requirement when working with plasmons, which are surface waves of light that can do what regular light cannot.

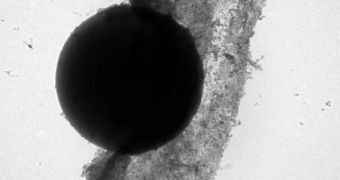

Plasmons can only be produced and controlled by shining light on specially patterned nanofilms, which have to be extra-smooth in order to guide the waves. Otherwise, they scatter, and the researchers cannot use films to manipulate them anymore.

“People have shown useful effects with plasmons, but the problem is doing it on a substrate you could cheaply and reproducibly make,” UM chemistry professor David Norris explains. He adds that, until now, experts have used high-energy ions or electrons to carve out various types of patterns within metal films, to allow for plasmon manipulation.

But, because each of the films was done “by hand,” there didn't exist two identical ones, so standardization efforts were in vain. In the new study, published in the latest issue of the journal Science, Norris and his team describe their new way of etching the patterns onto metal, which makes use of silicon molds.

The paper shows that, if the surface of the nanofilm were to be compared with the surface of the pond, plasmons would travel distortion-free, just as regular waves would on a still pond. The scattering effect can be compared with waves traveling over a lake and running into a leaf – their initial shape is destroyed. In the new method devised at the UM, researchers say that the distortion plasmons face is comparable to that waves on a lake would, if they slammed into a leaf about four-tenths of a nanometer thick.

“The top surface of the metal is now rough, but the bottom surface in contact with the silicon is quite smooth,” Norris says. The lithography techniques the team uses are taken directly from the semiconducting industry, where they are employed to pattern silicon. In the new set-up, they are covered with thin, metal nanofilms.

14 DAY TRIAL //

14 DAY TRIAL //