3D printing an object out of plastic or whatever is all well and good, but going from simple, single-material models to complex, multi-substance electronics is a tall order.

Neil Jansen and Karl Lew have accepted the challenge, having designed a machine that can automatically assemble a printed circuit board.

Basically, they've accomplished the goal of the Original RepRap project, without actually being part of the project themselves.

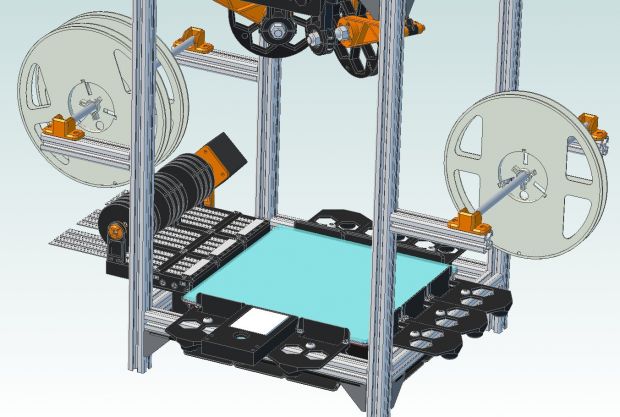

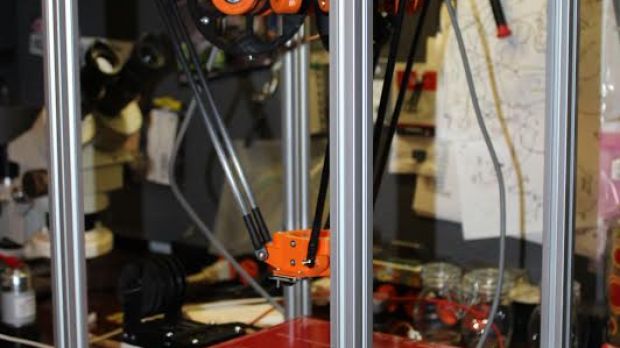

They decided to tackle the main issues one by one. They solved the placement of the electronic parts (how to pick them up and place them properly on the board), the tool changes, the accuracy, the component feeders (or how to get the components into the machine in the first place), soldering, ES safety, software, and even cost.

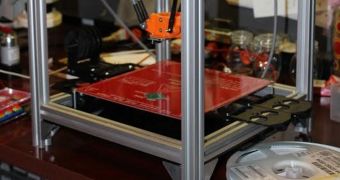

The machine is called FirePick Delta (that's the team's name too) and can 3D print prototype PCBs (printed circuit boards). They still need to refine the thing, a lot, but it shows that we're almost at the point where machines are able to build other machines from parts and raw materials.

It will still be a few years before you are able to create a device with a single press of a button, but the world is quickly getting there.

14 DAY TRIAL //

14 DAY TRIAL //