Have you ever heard of 3D printers with more than one filament extruder? So have we, but we bet you have never heard about the sort of printer that a man by the name of Tyler Anderson has just revealed.

The only reason 3D printers used more than one filament extruder in the past was to allow the combination of more than one filament, and thus, multi-color printing.

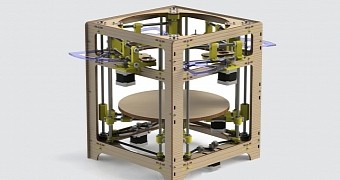

The new design submitted for the latest Hack A Day competition, however, is very different, in that it doesn't have all the four extruders brought together in a single whole.

Instead, the printer has them working independently, yet also in sync. Essentially, Tyler Anderson has invented a 3D printer that can print from four different points at the same time.

The applications of this method are many. You could use the printer to create an object in a quarter of the time, for one thing. Alternatively, you could use it to print several different objects at once, or several parts of the same object.

Anderson named his 3D printer “Theta” and gave it the ability to reliably use four extruders at the same time thanks to a polar coordinate system. The build plate rotates, you see, and the extruders move and print along its radius at the same time instead of taking turns.

Anderson had to install 10 stepper motors on his contraption in order to get it to work properly. It took him some thinking, but he did it.

Thus, you may now be in awe at the sight of this 3D printer which can create an object, or multiple objects, made of several materials and colors, all the while taking a fourth of the time it would normally necessitate.

The new system also has the advantage of less moving mass, leading to better acceleration, and by extension, superior print speeds as well.

There is one drawback though: the objects, or parts of objects, printed near the edge of the build plate will have lower quality than the central pieces because the build platform moves less there. Then again, its print resolution near the edges is still at least as good as the usual one, so this could be read as an advantage as well (higher quality for the center pieces as it were).

We can see high odds that this new 3D printer model could be adapted for factory assembly lines, as it can significantly increase the rate of production due to its ability to cut print time to a fourth of the norm. Maybe the number of extruders will even go up over time.

14 DAY TRIAL //

14 DAY TRIAL //