This is like a knife for the bacteria: a team at Rensselaer Polytechnic Institute has made a razor-like material on the "cutting edge" of nanotechnology. The nanoblades are made of magnesium and result from a different nanostructure growth technique than the traditional one. But we won't cut bacteria with them; they are connected to energy storage and fuel cell technology.

"The sharp nanometer-scale surface is vastly different from any other nanomaterial that has been created before using oblique angle deposition," said lead researcher Gwo-Ching Wang, professor and head of physics, applied physics, and astronomy at Rensselaer.

The almost two-dimensional nanostructure was achieved through oblique angle deposition, previously believed to create just cylindrical shapes like nanorods or nanosprings.

"Unlike three-dimensional springs and rods, nanoblades are extremely thin, with very large surface areas. They also are surprisingly spread out for a uniform nanomaterial, with one to two micron meters in between each blade. The materials could be extremely useful for energy storage, particularly hydrogen storage," said Wang.

Hydrogen needs a large storage area, which offers space for the expanding material as more hydrogen atoms are stored. The nanoblades have two properties: huge surfaces and big spaces between each blade.

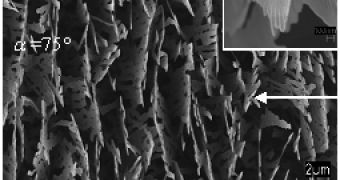

The nanoblades were made through oblique angle vapor deposition by vaporizing magnesium whose atoms were deposited on a surface at a specific angle. While the deposition angle shifted, the structure of the deposited material also changed. When magnesium was deposited straight onto a surface at zero degrees, the blades took the shape of a handful of flat, flaky structures overlapping one another.

By increasing the deposition angle, the blade shape turned apparent. The structures first inclined away from the direction of the magnesium vapor source, not towards the vapors' direction. Then, the blades rapidly curved upward to form the ultrathin nanoblades.

From the side, the nanoblades look like an overgrown lawn with nanoblade spires. At an angle of 75?, the nanoblades can be just 15 nanometers thick and a few hundred wide. To work for hydrogen fuel cells, magnesium nanoblades must be coated with metallic catalysts to store hydrogen.

The growing nanoblades were monitored through a reflection high-energy electron diffraction (RHEED) technique, which delivers the image of a surface, while previous diffraction techniques like X-rays observe the whole material, from the tip of the new nanomaterial to the substrate that the material is growing on.

Monitoring the surface explains the way the structure changes over time, enabling researchers to see the mechanism of nanostructure synthesis, a fact that could help researchers manipulate the creation of ideal future nanomaterials.

14 DAY TRIAL //

14 DAY TRIAL //