Texas Instruments is getting ready to manufacture the next generation of semiconductors as the company is currently perfecting a new method of growing graphene sheets which will eventually enable it to produce faster, smaller and lower power electronics based on carbon instead of silicon.

According to EETimes, Texas Instruments has recently demonstrated a method of growing graphene crystals up to half a millimeter in diameter.

The technology was developed by the company in collaboration with IBM's T.J. Watson Research Center, the Nanoelectronic Research Initiative (NRI), and the University of Texas and relies on using low-pressure chemical vapor deposition inside copper-foil enclosures, with methane as a precursor.

Right now, the resulting graphene films have to be transferred to doped single-crystal silicon and silicon-on-insulator substrates, but the team is working on developing a way to grow graphene directly on dielectric substrates.

This is TI's largest graphene film developed until now as the company's previous domains measured only 10 to 20 microns in size, about 30 times less than the 500 micron domains it has now managed to build now.

“This research is teaching us a lot on fundamental mechanisms of graphene growth,” said Texas Instruments' Fellow Luigi Colombo.

“We believe that the results of this work will lead scientists and engineers to further increase the size of the single crystal graphene and also improve the electrical characteristics of the material,” continued the company's official.

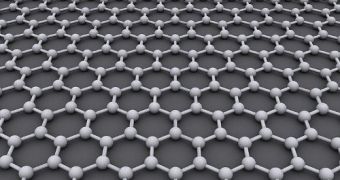

Graphene is two-dimensional allotrope of carbon made from a hexagonal lattice of carbon atoms and their bonds. This means, the material is just one-atom thick, paving the way for the fabrication of some of the smallest transistors possible.

However, both Intel and IBM agree that graphene won't actually replace silicon in the next generation processors as the material doesn't feature an energy gap, raising energy efficiency and gate signaling problems.

14 DAY TRIAL //

14 DAY TRIAL //