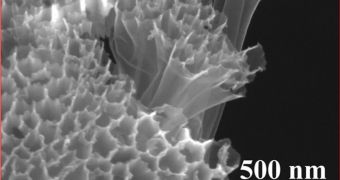

associate professor of materials science and engineering Yi Cui and his team were recently able to develop a superior rechargeable lithium battery cathode, a device which they say contains carbon nanofibers that are hollow on the inside, and coated with sulfur.

In addition, a new electrolyte additive is also used to boost the cathode's overall performances. The next generation of batteries, Cui believes, could consist of sulfur-coated carbon cathodes and silicon nanowire-based anodes. This setup appears to be capable of storing a lot of energy.

The new cathode will find important uses even in existing lithium-ion (Li-Ion) battery technologies. Science teams around the world currently agree that nanotechnology is a field of investigation definitely worth pursuing when it comes to creating better batteries.

New Li-Ion energy-storage devices are needed badly on all markets. Electric car manufacturers, for example, cannot sell their vehicles to a lot of people because of the low mileage the automobiles get per electric charge. Better batteries would equal higher mileage.

“I strongly believe that's a promising future choice to make better batteries,” Cui says, referring to the silicon/carbon combo. “Sulfur is one of the materials that can offer a 10-times higher charge storage capacity but with about half the voltage of the existing battery,” he adds.

Details of how the new battery design looks like appear in the September 14 online issue of the esteemed scientific journal Nano Letters. The team says that stopping the sulfur cathodes from failing due to repeated charging and recharging was their biggest challenge.

By using hollow carbon nanotubes in the production process, the Stanford team was able to eliminate a large number of problems that, when added together, “represent a really big challenge to get this material to work as a viable battery,” Cui says.

The study team also included Stanford Department of Materials Science and Engineering investigator Judy J. Cha and Department of Applied Physics research scientist Seung Sae Hong. Wesley Guangyuan Zheng, a graduate student in Cui's lab, was also a member of the team.

The new additive the team developed also plays an important role in boosting silicon/carbon Li-ion batteries. “Without the additive you put 100 electrons into the battery and you get 85 out. With the additive, you get 99 out,” the team leader explains.

“To design the best structure we need both the electrode design and the electrolyte additive and these two combined together can give you a high capacity and high coulombic efficiency. We now have high capacity on both sides of the electrode; that's exciting,” Cui concludes.

14 DAY TRIAL //

14 DAY TRIAL //