The idea of solar cells is so cool! They would come with such cheap energy, and everybody would be a Captain Planet fighting pollution. But what many people still do not understand is that they are so inefficient at this moment. A new research published in "Applied Physics Letters" could come with a step further to the moment when solar energy will be most of the energy we use daily.

"Some of that inefficiency is due to the fact that silicon is reflective. There are disadvantages to the anti-reflective coating currently used in solar cells. You want more of the sunlight absorbed, rather than reflected," Peng Jiang, an assistant professor at the University of Florida, told PhysOrg.com.

His team is inspired by the structure of moth eyes for solving these disadvantages, for better and cheaper solar cells.

"Right now, the bluish anti-reflective coating you see on solar cells is not very efficient beyond a narrow range. The wavelengths of light from the sun range from between 400 nm and 1400 nm. Once you get below about 500 nm, and above 800 nm, reflection starts increasing. The optimal efficiency for the current technology works with wavelengths of around 600 nm," said Jiang.

"Moth eyes are not very reflective. We found our inspiration in nature, trying to mimic the natural nanostructure," he added.

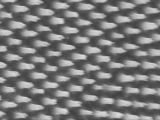

Moth eyes have orderly bumps on their corneas, and that pattern impedes reflection. This is a protection against night predators: moths cannot be seen because of the light reflected by their eyes.

"A method of spin coating is used to create the effect," said Jiang. Nanoparticles in a liquid suspension are located on a silicon wafer (as employed in solar cells) and the spinning of the wafer distributes the nanoparticles in the liquid. An etching template creates the desired pattern by transferring the nanoparticle structure onto the silicon wafer.

"It is self-assembling. All of the particles are the same size. It's like when you put glass beads in a box and then shake it. All of the beads arrange themselves into an array pattern. This process creates less than 2% reflection. This is a vast improvement over the 35 to 40% reflection rate seen without the anti-reflection coating layers. This simple, cheaper process is also much more efficient," said Jiang.

"We are close to a start-up company that could use this process to make solar cells. Right now, this is done with single crystalline silicon wafers. We hope to extend the technology to work on multi-crystalline silicon, which is where solar cell technology is moving in the future," he added.

14 DAY TRIAL //

14 DAY TRIAL //