In their quest to improve the capabilities of nanotechnology, scientists have tried out all sorts of methods of producing nanoscale fabrics, as well as artificial tissues, for use in transplants and smart clothes. Thus far, these techniques only recorded minor successes, but a new approach may be exactly what the scientific community has been waiting for. Experts from the Harvard University Wyss Institute for Biologically Inspired Engineering, together with colleagues from the School of Engineering, managed to produce a self-assembling nanoscale matrix, which can underlie future generations of synthetic tissues and smart clothes.

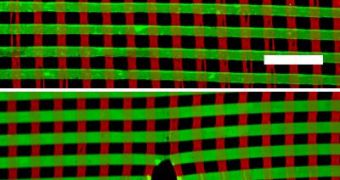

Whenever investigators – from a wide variety of fields – turn their eye to nature, they always feel inspired. This is precisely what happened during the new research, when the Harvard experts looked at how cells and tissues assemble and organize themselves inside a matrix of protein fibers. It's this matrix that eventually dictates the final structure of the cells, as well as the ultimate tissue function. Some of the features that are dictated in this manner include the heart tissue's ability to contract, as well as the level of elasticity the human skin has. What the research team did was to basically replicate in the lab the principles on which nature relies to create these structures.

“To date it has been very difficult to replicate this extracellular matrix using man-made materials. But we thought if cells can build this matrix at the surface of their membranes, maybe we can build it ourselves on a surface too. We were thrilled to see that we could,” says Harvard postdoctoral fellow Adam W. Feinberg, who recently received an appointment as an assistant professor at the Carnegie Mellon University. He explains that the key behind the new innovation was the development of a synthetic matrix material that is able to self-assemble when coming in contact with thermo-sensitive surface. The proteins in the matrix itself can be varied according to needs so that specific, desired properties are developed.

According to the team, the resulting nanoscale fabric can be obtained by simply going through with this process, and then altering the temperatures of the matrix. This allows for the fabric to separate, and then researchers can harvest it. Details of the new investigation appear in the latest issue of the American Chemical Society's respected journal Nano Letters. Feinberg was the lead author of the scientific paper accompanying the findings, called “Surface-Initiated Assembly of Protein Nanofabrics.”

14 DAY TRIAL //

14 DAY TRIAL //