There are a whole bunch of different methods of achieving additive manufacturing, but they can usually be classified into one of several broad categories. Chinese scientists have just unveiled a technique that can't so easily be labeled though.

Let's see. We have FDM 3D printing, the most common technique, which pushes plastic filament through a super-hot extruder in order to build objects drop by drop.

We also have SLA, where a tank of resin is bombarded with ultraviolet light, and cured until it becomes solid. This technology literally grows objects out of resin.

There's also laser sintering, mostly used for metal. A powder is subjected to a high-temperature laser, melted and added to the object being created.

The new technology from the Beijing Key Laboratory of CryoBiomedical Engineering is called liquid phase 3D printing and is intended to quickly manufacture conductive metal objects.

The liquid phase 3D printing technology

The Beijing Key Laboratory of CryoBiomedical Engineering is part of the Technical Institute of Physics and Chemistry at the Chinese Academy of Sciences.

A team of researchers there developed a type of 3D printing which uses ink (term loosely used) made of a metal alloy whose melting point is only a bit above room temperature. Pretty much like some kinds of chocolate we know, now that we think about it.

A four-element alloy called Bi35In48.6Sn16Zn0.4 turned out to be the key, although they had to make sure their printing technique measured up too. They had to prevent the ink from oxidizing, for one thing, which is a common issue in air cooling during conventional 3D printing of metal “inks.”

The object first has to be designed in CAD software, then converted to an STL file (STereoLithography file). That done, the file is imported to an open source software program that slices it horizontally, then generates tool paths for the resulting layers.

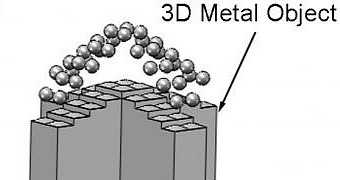

After that, all that's left is for the ink to be dropped into a liquid phase cooling fluid through an injection needle. The final quality hinges on the properties of the printing ink (gallium, bismuth or indium based, or a mixture of them and nanoparticles).

Interestingly enough, there are clear advantages to the new technology: manufacturing speed, greater ease in producing 3D structures, flexible control of the temperature field and flow field of the cooling fluid (water, ethanol or something else), etc. You can even print 3D rotating bodies and 3D electromechanical systems.

In fact, you can even alternate conductive liquid metals with plastic to form 3D devices with supporting structures and electric circuits inside.

The flexibility of the technology

Any metal with a low cooling point (less than 300°C / 572 °F) can be selected for the printing ink, as long as the alloy is made with the materials mentioned before (gallium, bismuth, or indium) and an appropriate cooling liquid is available.

14 DAY TRIAL //

14 DAY TRIAL //