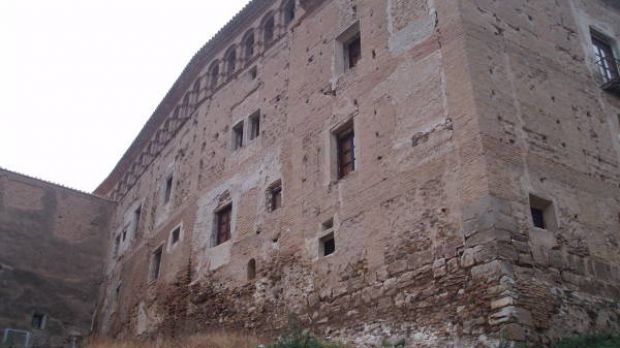

Ever since Ancient time, when mortar, concrete and cement were not your average commodities in the world, people have employed an old constructions technique that was equally cheap and green. With the use of rammed earth, engineers of old managed to erect impressive structures, ranging from garrisons to churches and nobility mansions. Now, experts at the Durham University School of Engineering are looking into that Ancient construction technique, hoping to find what makes it “tick” and to adapt it to 21st century demands.

In the course of their studies on the rammed earth method, the British engineers learned that the most important aspect of the entire process is determining the correct amount of water. They likened this type of material to the sand in a sandcastle – while you build it, you have to have water in order for it to stick. Too much water, and the entire structure falls into a pile of mud, too little water, and you can't get the sand to stand up in the first place. The research team learned that, as with sand, rammed earth too needs to have at least a minimal amount of water in it, in order to stick.

Basically, this material is made up entirely out of gravel, sand and clay, which are then poured into shapes, just like in a mold. Once the mix dries up, it becomes strong, and its strength can also be augmented with such stabilizers as cement or other material. The Durham University team focused on the kind of rammed earth that featured no stabilizers to speak of. The results of their investigation were published in the latest issue of the scientific journal Geotechnique, and the research was sponsored by the Engineering and Physical Sciences Research Council (EPSRC).

The experts also found out that one of the reasons why the rammed earth was so strong even after rigorous testing was the fact that suction appeared between soil particles at very low water contents inside the wall itself. This means that, even when left out to dry, the material never lost all of its water, and became enormously strong over time. The find could have serious implications for the construction industry, which could in the future use forms of rammed earth rather than the cement it currently does.

“We know that rammed earth can stand the test of time but the source of its strength has not been understood properly to date. Without this understanding we cannot effectively conserve old rammed earth or make economic designs for new build. Our initial tests point to its main source of strength being linked to its water content. By understanding more about this we can begin to look at the implications for using rammed earth as a green material in the design of new buildings and in the conservation of ancient buildings that were constructed using the technique,” said Dr. Charles Augarde, Durham University School of Engineering research project leader.

“This kind of research is very valuable as the construction industry analyses environmentally sound, traditional ways of building and adapts them for sustainable construction in the 21st century. Such low-carbon technologies are most likely to succeed by marrying the expertise of our research universities, such as [DU], with the commercial understanding of the wider industry and we are seeing a number of very exciting developments in this area,” concluded the Secretary of Earth Building UK, Tom Morton. The organization is dedicated to fostering the conservation, understanding and development of rammed earth buildings in the UK.

14 DAY TRIAL //

14 DAY TRIAL //