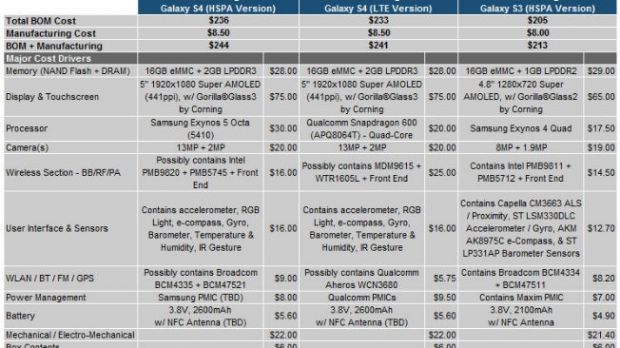

With a bit more than a month left until the Samsung Galaxy S 4 hits shelves in select markets, the raw costs of producing the device have just been unveiled by IHS iSuppli's virtual teardown.

CNET reports the costs for making one Galaxy S 4 unit are 15% higher than the previous model. However, given the new upgrades the Galaxy S 4 embeds in comparison with its predecessor, the slightly higher manufacture costs are not that high at all.

According to an IHS iSuppli virtual teardown, Samsung Galaxy S 4 costs around $244/€190 to manufacturer, while the LTE version is a bit cheaper at $233/€180.

“Among the upgrades are a larger, full high-definition (HD) display; a beefed-up Samsung processor; and a wealth of new sensors that set a record high for the number of such devices in a smartphone design,” said Vincent Leung, senior analyst for cost benchmarking at IHS.

From what we can tell, the highest price Samsung has to pay is for the 5-inch Super AMOLED capacitive touchscreen display that supports full HD (1080p) resolution and features Corning Gorilla Glass 3 coating.

This kind of display is said to offer enhanced AMOLED technology in comparison with Galaxy S III’s screen and is priced by HIS at no less than $75/€60.

Furthermore, the chipset that Samsung is using for the international version of Galaxy S 4, the Exynos 5 Octa is priced at $30/€23, whereas Galaxy S III’s chip only costs $17.50/€13,50 to make.

The US variant of Galaxy S 4 users Qualcomm’s Snapdragon 600 chipset that packs a quad-core processor clocked at 1.9GHz and LTE radio. This chipset costs only $20/€15,50.

More info on the costs of different parts and components of the Samsung Galaxy S 4 are detailed in the images attached to this article, courtesy to IHS iSuppli.

14 DAY TRIAL //

14 DAY TRIAL //