Back when we got invited in Japan, by Sony, we were also able to take part in a series of talks with the Sony Vaio engineers and the people that work at the company's Nagano facility. Thanks to these sessions, we were able to better understand the company's strategy when designing and building a new computer. What we found out there we'd like to share with you today, as it pretty much resumes the way Sony's latest Vaio P portable computer was designed, but also how the company's X and Z series materialized in the products they are today.

As most of you know, Sony's VAIO brand isn't one that most users can afford, but the company has a good track of coming out with some very interesting designs. The latest VAIO P doesn't fall short of it and improves on a product that has drawn the audience attention back at CES 2009, when it was first released. That is the result of a good design, which provides the end-user with a mix of aesthetics and nice hardware. Well, that design comes out of the company's new strategy to incorporate all of the required steps for a new product design, into one initial step.

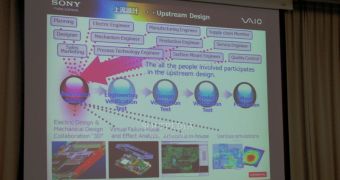

Let's just stop for a while and lay down the details of what we are referring to. When the decision is made for a new product to enter production stage, it has to follow a series of steps and procedures before it can be packed and shipped to consumers. This is a process that Sony wanted to improve to lead to a better mass production of its VAIO laptops. The way they did this is by involving all engineers into the initial design stage.

Basically, SONY's upstream design takes everything from when the product is ready for market and gathers it around this initial step for every new computer that is rolled out of its manufacturing line. For example, if one of Sony's engineers would come with an idea for a new computer, he will then join all the other engineers, such as the electric engineer, the process technology engineer, the manufacturing engineer and so on. According to Sony, this process is more efficient and enables the company to accelerate product development and consequently roll out new products on the market.

The Nagano facility we visited last month was built to accommodate this specific purpose, namely to have the entire design team in one place, so that any problem that could surface throughout the manufacturing process could be tackled immediately. As we previously mentioned, the Vaio P was built using this design scenario, which enabled Sony to shorten the design process of the second model, as opposed to that of the first model.

The same upstream design was also used for a couple of Sony's other portable computer systems, such as the Z-series, which led us to believe that the company's high-end systems are bound to take advantage of the same technology. However, it appears that this upstream design concept will be adopted across the company's entire line of VAIO laptops.

14 DAY TRIAL //

14 DAY TRIAL //