Future nanodevices will be structures that are extremely small, and that will play a huge host of roles, both in the human body and in the industry. However, in order to make them operational, very small wires, called nanowires, are needed. These structures are made from such materials as gold, silver or, in some instances, silicon and carbon. The metallic variety is to be used in small electrical devices. The main problem around them is that no one really knows how they behave when subjected to stress.

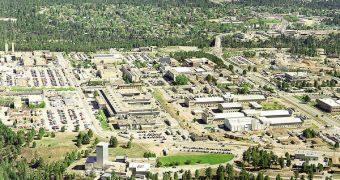

And this is precisely why scientists at the US Department of Energy's (DOE) Los Alamos National Laboratory (LANL) recently used the world's most advanced supercomputer, the IBM Roadrunner, to simulate the behavior of silver nanowires over a period of milliseconds. This was the most accurate such simulation ever conducted, and experts believe that the results are the closest hypothetically possible to the ones that would be recorded in similar situations in real life.

“Bigger supercomputers have made it possible to perform simulations on larger and larger systems, but they have not helped much with reaching longer times – the best we can do is still about a millionth of a second. However, with the parallel-replica algorithm, we can utilize the large number of processors to 'parallelize' time. Roadrunner is ideally suited to this algorithm, so now we can do simulations thousands of times longer than this,” LANL Theoretical Division scientist Arthur Voter says of the reasoning behind the new simulations.

“Molecular dynamics simulations have been around for a long time, ” Arthur Voter adds about the Theoretical Division atthe Los Alamos National Laboratory. “But the simulations have never before been able to mimic the atomistic tensile strength of nanowires at time scales that even come close to experimental reality,” he adds. The main advantage of the new simulations is that they can assess the behavior of nanowires under prolonged periods of stress, which will help materials scientists understand where their future designs need reinforcements.

“At longer time scales we see interesting effects. When the wires are stretched more slowly their behavior changes. The deformation and failure mechanisms are very different than what we've seen at shorter time scales,” Voter explains.

14 DAY TRIAL //

14 DAY TRIAL //