Mushrooms, the fleshy spore-bearing fruiting bodies of fungi typically produced above ground on soil or on their food sources, are good on pizza and even for getting high. Indoor, the ones growing on the walls are considered harmful and inaesthetic and make a bad impression on visitors.

Not anymore. A group of young researchers developed a new technique that uses ordinary mushrooms as thermal insulators for walls. Sustainable insulation applications are about a year away from hitting the market, but recent tests at the National Institute of Standards and Technology have shown it to be competitive with most insulation brands on the market.

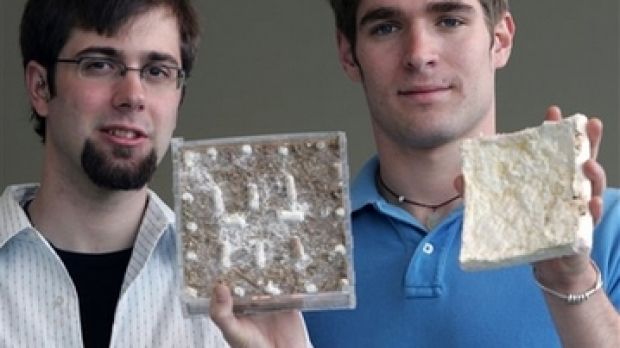

Eben Bayer, a Rensselaer Polytechnic Institute graduate, and colleague Gavin McIntyre, created the patented "Greensulate" formula, an organic, fire-retardant board made of water, flour, oyster mushroom spores - the second most widely cultivated mushroom in the world - and perlite, a mineral blend found in potting soil.

The two researchers are very young, 21 and 22 years old, respectively and hope their idea will soon be part of the growing market for eco-friendly products, allowing them to bear the financial fruits of the invention in their best years.

"We've been growing the material under our beds," said McIntyre. They have already applied for a grant from the National Collegiate Inventors and Innovators Alliance. The mixture is created by pouring water, starch, hydrogen peroxide and mineral particles into 7-by-7 inch molds, in which living mushroom cells are being injected. The hydrogen peroxide is used to prevent the growth of other specimens within the material.

When placed in a dark space, the mushrooms start to grow, digesting the starch as food and sprouting thousands of root-like cellular strands. It only takes around two weeks for a 1-inch-thick panel of insulation to fully grow, which is then dried to prevent fungal growth, making it unlikely to trigger mold and fungus allergies.

"I think it has a lot of potential, and it could make a big difference in people's lives," said RPI Professor Burt Swersy, whose Inventor's Studio course inspired the product's creation. "It's sustainable, and enviro-friendly, it's not based on petrochemicals and doesn't require much energy or cost to make it."

Preliminary results are very promising, a 1-inch-thick sample of the perlite-mushroom composite probing to be as resistant to heat flow as most commercially available fiberglass insulations.

14 DAY TRIAL //

14 DAY TRIAL //