Researchers at the North Carolina State University have reportedly published a scientific paper on a copper-graphene alloy that can be used as the building material for future heatsinks.

The paper concludes that the new type of alloy will show much better cooling performance than current, pure copper solutions.

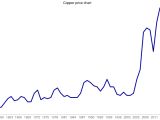

Over the past two decades, the price of copper has increased tremendously and currently, mining companies around the world are fighting for the rights to explore and exploit the last areas that are known to contain such type of ore.

Just imagine how much higher the price of a pure copper cooler weighing around 800 grams is now, when the price of copper as a commodity has increased by nearly 400% since 2002, compared to the price of a similar solution built 10 years ago.

The profit margins in the cooling business have decreased in the past years and, when researchers find a way to make the products better while being cheaper to manufacture, every cooling company pays attention.

“Both the copper-graphene and indium-graphene have higher thermal conductivity, allowing the device to cool efficiently. The copper-graphene composite is also low-cost and easy to produce. Copper is expensive, so replacing some of the copper with graphene actually lowers the overall cost,” said Dr. Jag Kasichainula, professor of materials science and engineering at North Carolina State and head author of the research paper.

The cooling improvement is greater than 25% when compared with standard, pure copper cooling solutions. This percentage is high enough to get the attention of after market cooling manufacturers and even standard solution builders.

The find is not without limitations. For now, there are some strict ranges in which these improvements were observed.

The improvement in thermal conductivity increased from 380W/mK to 460W/mK at 300K, that’s around 27 degrees Celsius, but the thermal conductivity of the copper-graphene alloy decreased from 510W/mK at 250K, (-23 degrees Celsius) to 440 W/mK at 350 K (around 77 degrees Celsius).

While these limitations are not desirable, the solution found in the research is very valuable for most of the cooling solutions that must ensure stable working temperatures between minus 23 degrees Celsius to 77 degrees Celsius.

14 DAY TRIAL //

14 DAY TRIAL //