A group of investigators announces the development of a new method of producing graphene. The material is hailed as the next big thing in the electronics industry, due to its remarkable physical and chemical properties. But producing the stuff with the maximum level of purity and in large amounts has thus far proven to be extremely difficult, and cost-intensive. The new approach, which is based on fluid-processing techniques, was developed by researchers in the United States, at the Rice University, and the Technion-Israel Institute of Technology, PhysOrg reports.

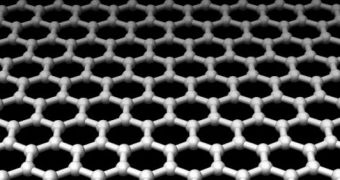

Graphene is a carbon compound that boasts a thickness of only one atom. As such, it can accurately be characterized as two-dimensional. Its atoms are arranged in a honeycomb-like, hexagonal structure, and this allows for it to exhibit some very interesting properties. The material was discovered some 6 years ago by scientists at the University of Manchester, in the United Kingdom, and has been heavily researched ever since. It can be obtained from graphite, the compound that makes pencil leads, by peeling away individual layers. The result is an ultra-strong, highly conductive material, experts say.

“There are high-throughput methods for making graphene oxide, which is not as conductive as graphene, and there are low-throughput methods for making pure graphene. Our method yields very pure material, and it is based on bulk fluid-processing techniques that have long been used by the chemical industry,” says Rice professor of chemistry and chemical and biomolecular engineering, Matteo Pasqualo. He is also the lead co-author of a paper describing the findings, which appears in the latest online issue of the esteemed scientific publication Nature Nanotechnology.

The new method revolves around using chlorosulphonic acid. Graphite is placed inside the common industrial solvent, and then researchers measure to see how the flakes assemble themselves. At the start of the study, the team expected to find only small amounts of graphene in the solution, but analysis revealed that the compound peeled in the correct layer conformation spontaneously. The investigators say that their method produces about 2 grams of the stuff per every liter of acidic solution, which means that their technique is about 10 times more efficient than any other currently being used.

“We applied new methods that we had developed to directly image carbon nanotubes in acid. This was no small feat considering the nature of the acid and the difficulty of specimen preparation and imaging,” explains Technion-Israel Institute of Technology professor of chemical engineering Yeshayahu Talmon, who was also a coauthor of the work.

14 DAY TRIAL //

14 DAY TRIAL //