In a new study published online in the September 13th issue of the journal Nature Materials, experts at the Eindhoven University of Technology (EUT) and the University of Ulm announced that they had managed to get high-resolution, 3D images of the inside of a polymer solar cell for the first time. Knowing the nanoscale structure of these polymers is vital towards understanding the way the solar cells act, and how much energy they output, the team says.

At this point, polymer solar cells are still far behind their silicon counterparts, as far as performances go. But their main advantage is the fact that they can be printed in a roll-to-roll process, very fast and in large quantities. This ability that they have can potentially make them highly cost-effective. They can also be incorporated in vehicles, clothes and other objects, but they first have to be brought to a higher performance level. And this is where the new, 3D images come in.

Polymer solar cells are generally made up of metal oxide nanoparticles and various types of polymers. When the mixture is illuminated by sunlight, the interface between the two compounds generates charges. But controlling the exact nanoscale structure of the interface is very hard to do. Intimate mixing of the two is very effective in terms of extracting power, but the charges take a very long time to start flowing in external circuits. If the domain is larger, then the effect is exactly the opposite.

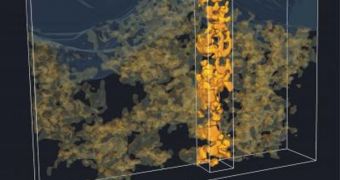

In the new experiments, 3D electron tomography was used to demonstrate the importance of the degree of mixing in determining the absorbed photon rates in the polymer solar cells. In an approach devised at EUT, a 50-percent absorption rate was obtained, by using a metal precursor that was mixed to the polymers before the imprint process started. It's only afterwards that the precursor was turned into metal oxide. This approach proved to be highly successful in lab tests.

The new study, dubbed “The effect of three-dimensional morphology on the efficiency of hybrid polymer solar cells,” was authored by expert Stefan Oosterhout, and funded by the Joint Solar Programme of FOM, NWO, the Shell Research Foundation, the Deutsche Forschungsgemeinschaft, SenterNovem, and the Dutch Polymer Institute.

14 DAY TRIAL //

14 DAY TRIAL //