The team of researchers at Fraunhofer Institute for Building Physics, have been working on new ways to process the ETFE film facades, and they will present their results at fair BAU 2011 from January 17 to 22 in Munich.

The plastic film ETFE is a revolution for architects and for the construction business, since it makes possible totally different designs.

The best examples of the prowess of plastic sheets, are the Eden Project in Southern England, the National Aquatics Center built for swimming events at the Olympics in Beijing and the Allianz Arena in Munich.

This material, does not only look futuristic, it is also very advanced and it can insulate and control heating in buildings.

ETFE stands for ethylene tetraflourethylene, which is a transparent membrane, mostly popular since it enables buildings that shine in many colors, like those in Munich and Peking, but the material can be used for much more than that.

It could cover existing buildings and regulate heat, coolness and light, according to everyone's needs, and it seems that these features should make it a very popular material on the future construction market.

Now it's only a matter of making the material low-cost, easy to process and clean of all health hazards, before it can stand a chance in the international construction business.

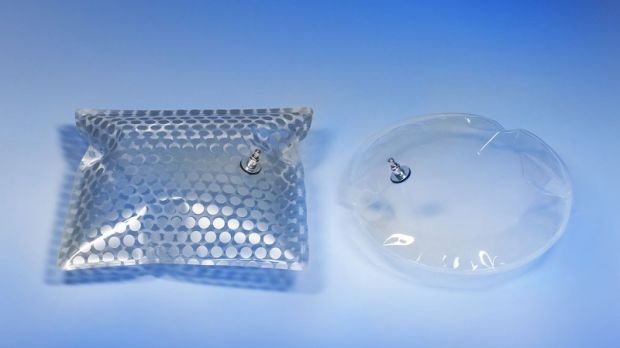

This is actually the goal of the six Fraunhofer institutes, which are working jointly as part of the Multifunctional Membrane Cushion Construction project.

So far, the engineers manged to specifically change the properties of ETFE fois, by using different coatings.

This way, you could regulate the passage of light thanks to membrane cushions with an inner coating of tungsten trioxide, that turn blue when they come into contact with hydrogen and lose their color if the cushions are filled with oxygen.

Andreas Kaufmann of the Fraunhofer Institute for Building Physics (IBP) is the project coordinator, and he explains that “you could use a foil such as this to cover the entire facade of a house and have light pass depending upon sunlight conditions.”

Another problem that has been solved is turning the ETFE membranes into heat barriers, thanks to a coat of paper-thin layers of aluminum and pain.

In this case the real “challenge was overcoming the anti-adhesive properties of the membrane,” said Kaufmann.

“ETFE is related to the anti-stick substance Teflon and hardly reacts with other substances chemically.

“This is why the surface of the foil first has to be pretreated chemically before coating.”

And since most things come in three, the researchers also came up with antibacterial layers, that prevent the growth of mold and yeasts.

Robert Hodann, the CEO at film manufacturer Nowofol and industrial partner of the research project, says “that ETFE will emerge as a strong market of its own.

“The captivating thing about ETFE foil is its transparency combined with its great strength – no other plastic membrane can compete.”

14 DAY TRIAL //

14 DAY TRIAL //