Full-color 3D printing is hard to come by. There are one or two printers that can pull something like it off, by using multiple extruders to combine materials. Others just use a multicolored filament spool, at the cost of having no control whatsoever on what is colored and how.

Now, though, a patent has been filed, one that describes a method of coloring filament while the printing process is going on. The technology was filed back in October 2013, but has only now been published.

The patent was filed by Evonik Industries Ag, a German chemical manufacturing company, but is credited to a group of eight people: Markus Pridoehl, Guenter Schmitt, Dirk Poppe, Stephan Kohlstruk, Benjamin Hammann, Sonja Cremer, Kris Beks, and Ludo Dewaelheyns.

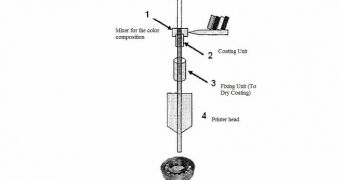

In a nutshell, their planned invention would have two extra units above the print nozzle. One would coat the filament with an additive composition, which includes colored dye. This unit would have one or more nozzles, with a print head not unlike those found in inkjet printing.

The head would produce ink or dye and spread it over the filament. This would occur before the material passed through the second unit.

Said second unit would dry the coating. Only after that would the filament finally pass through the nozzle and be melted (that's how FDM 3D printing works, by melting plastic and using it to build objects drop by drop).

There is another way defined in the patent though. The material would pass through something quite similar to a sponge, but saturated with colored ink.

Just what method the second nozzle uses to dry the filament is not set. It could be an air drying mechanism between the coating unit and the print head, it could be a chemical reaction, or it could even be microwave radiation that would accelerate the drying process.

Finally, the patent describes a way to coat the filament in inorganic additives instead of paint, to give the printed objects certain unusual properties like surface conductivity, haptic properties, a certain degree of thermal conduction or isolation, etc. For example, filament could be coated in silicon oxide, aluminum oxide or carbon black. Even graphene is pegged as a possible layer, for its great electrical and thermal conductivity.

In theory, this means that all future 3D printers could be able to create circuits or other conductive units as long as you have the materials and special extruder addons.

14 DAY TRIAL //

14 DAY TRIAL //