3D printing technology is the sort of thing that many people in the world expect to see evolving into the kind of all-purpose automated manufacturing techniques seen in science fiction books, films, and games. PARC researchers have just revealed a key advancement here.

Technically speaking, additive manufacturing technologies have been in use for about 30 years. It's only been 2 or 3 since consumers gained access to it though.

That won't be out focus this time, however. You see, while the common man is playing with FDM and SLA 3D printers, manufacturers and scientists continue to research better ways of improving the original applications: product manufacture.

MIT Technology Review reports that researchers from PARC in Palo Alto, California, have invented a way to add electronic components to 3D printed objects.

It's not possible to just feed a 3D printer the different materials (powders, filaments, clay, resin, etc.) and just press a button to get your power glove.

No, right now the tech is still progressing, which means that some elements it has to have pre-fabricated before it can do what it's supposed to.

That's what the latest PARC project is about: a 3D printing process that can incorporate small “chiplets” in new 3D prints.

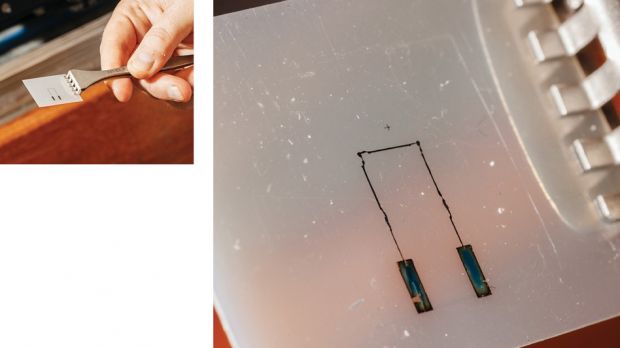

The chiplets are electronic devices, chips, cut from bulk wafers. They are the width of a human hair and are mixed into an ink solution. Definitely not the standard “chips” you might be familiar with (CPUs, GPU, DRAMs, ICs, etc.).

While in ink form, the chiplets are provided with positive and negative charges, then guided exactly to the spots they are supposed to take by electrical fields generated by wires arranged in a spiral. A glass substrate acts as support for everything.

After that, a specialized roller picks up the chiplets and places them on a second, different substrate made of plastic. Then, a special 3D printer wires the chiplets together.

Kind of dry, this theory, but the point is that this allows a 3D printer to incorporate electronic circuits into any object it is 3D printing, provided the model is modified to include them or designed with them in the first place.

Possible applications include flexible electronic gadgets, tiny sensors or sensor arrays, 3D objects with integrated computing functions (like toys that can move or make noise), or even to embed mini computers into 3D printed objects. All of them doable from your own home, since this “chiplet” process can be adapted to any additive printing technique, even common FDM.

14 DAY TRIAL //

14 DAY TRIAL //