Ithaca, New York-based company Orthogonal is currently working on an innovation that will allow organic electronics to be manufactured from the same equipment that currently produces silicon electronics. This line of research could bring about a new wave of innovation in the electronics industry, as organic semiconductor materials hold a lot of promise in new classes of devices, as replacements for the rigid silicon that is currently the basis of our technology. More efficient, lightweight and flexible solar cells could also be produced from the same materials.

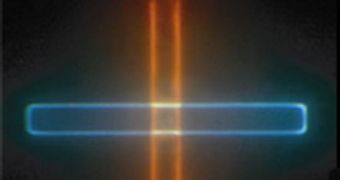

If Orthogonal manages to go through with its plan, then the resulting technology could be used in the future to create even more complex organic electronics than currently planned, as the technology to produce advanced electronics already exists. Among the four prototype devices that the company managed to create using its proprietary method, it mentions an organic light-emitting diode (LED), which was made employing new photolithography chemicals that were compatible with organic materials.

This process – photolithography – is one of the most common stages in microchip and transistor manufacturing processes. Essentially, boards of circuits are exposed to ultraviolet radiation, as harsh chemicals are dissolved over a silicon substrate. By simply changing the catalyst substances used in the reaction, the company's team managed to modify the lithographic process to such an extent that it allowed for the creation of completely different transistors. And one of the main advantages that the innovation brings forth is the fact that it spares most manufacturers from having to undergo expensive equipment replacements in order to produce the organic materials.

The main disadvantage of organic materials, such as polymers, is that they work relatively slower than silicon-based devices. However, they have only a fraction of the power requirements that their more advanced “cousins” have, and could also be cheaper to mass-produce and implement. “It's definitely an issue for organic light-emitting diodes and other organic electronics that a lot of the equipment is handmade. If you could use photolithography to make these devices, potentially you could break that bottleneck,” Paul Semenza says, quoted by Technology Review. He is the senior vice president of market research company DisplaySearch.

14 DAY TRIAL //

14 DAY TRIAL //