The ability to make any sort of shape is the primary asset of 3D printing technology, but there's another one just as important: the ability to switch materials as easily as switching filament spools. Sure, there are limits, but the MakerBot Replicator line has just overcome one of them.

The limits we're talking about is that not any sort of substance can be forced through a superheated extruder and be layered according to a 3D model.

Some materials don't have the needed consistency, others have different melting points, and others just can't be turned into filament at all. They may be too brittle or too stiff.

That's why filaments have to be made of plastic or some polymer or other with a similar enough mechanical and chemical behavior.

The news we have for you today is that a group of researchers from the University of Central Lancashire (UCLan) have created a 3D printing filament made of medicine.

The 3D filament made of drugs

Before you ask, no, we are not on drugs. Puns aside, the research team led by Dr. Mohamed Albed Alhnan have created a drug-polymer filament that can be used for almost any desktop 3D printer on the market.

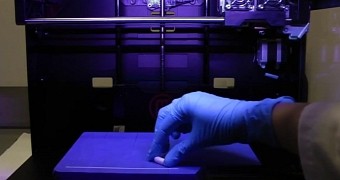

They themselves used a MakerBot Replicator 3D printer for tests, but most printers use 1.75 mm filament, so compatibility shouldn't be an issue.

The tricky part was making sure that the filament had (mostly) the same behavior when melted by the superheated extruder, and deposited through the narrow nozzle on the print bed.

Obviously, the scientists didn't intend for the product to be used in overly intricate objects, although it should be possible.

But really, who's going to make a piece of jewelry or figurine out of medicine? Besides, while the medicine can melt and be deposited drop by drop according to a 3D model well enough, the end products aren't as sturdy. After all, they're supposed to be easily digested by the human body.

Thus, the researchers have been making only tablet medicine. Pills if you're looking for the layman’s term.

Practical applications

The UCLan team believe that pharmaceutical companies could stand to gain much from the new technique if they adapt it for larger 3D printers that would be able to make tablets in bulk. The pills can essentially be produced according to the precise needs of each customer.

According to the scientists, drug stores and their parent corporations could start using the technology as early as 2019, less than 5 years from now.

14 DAY TRIAL //

14 DAY TRIAL //