Nike has been a major brand on the footwear market for many decades now, which means that it knows when to abandon an idea and when to adopt one. In this case, a situation of the latter type has arisen.

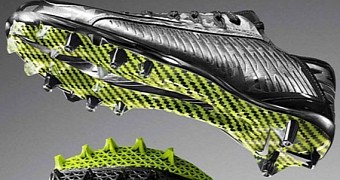

You may or may not have learned about the 3D printed Nike cleats, but you'll probably be unable to dodge mentions of 3D printed shoes from now on.

That's because the company has decided to focus a fair amount of its resources on the development and sale of 3D printed footwear.

Since Nike has already experimented and refined pretty much every other available design and manufacturing technique when it comes to shoes, it is pouncing on 3D printed because it sees a new path worth mastering.

Information in manufacturing is key

Nike President Mike Parker is of the opinion that the company's success relies on the continued evolution of manufacturing capabilities and ideas.

That's understandable, since the balance between supply, demand, cost of production and shoe endurance is one that it cannot afford to damage.

However, 3D printing technology offers the chance to cut down on the cost of production, and by extension, the final prices of footwear and related items.

Sports equipment and apparel will, of course, be at the forefront of this new business tactic, even if Nike is still, at least partially, in the experimental stage.

It's also the segment most likely to show palpable revenue increases, or drops, in the relatively short term. Basically, it's the best testing ground.

Nike has other innovation opportunities of course, according to Parker himself, but “3D printing […] has tremendous opportunity for [them].”

What you can expect to see from Nike in the future

Unfortunately, there are no concrete plans in place. Or if there are, Nike isn't sharing them with the rest of the world just yet. Fortunately, we can guess well enough.

Among the major assets of 3D printing is that shoes can be created to perfectly fit people's feet. You can have the sole of your left shoe turn out a bit thicker than the other one, or vice versa. You can also have one be slightly longer.

It all boils down to balance, and the ability of 3D printing to maximize it for all shoes built by means of this technology. In a way, price accessibility and new color choices are just some of the side benefits.

14 DAY TRIAL //

14 DAY TRIAL //