Investigations in the X-ray spectrum are critical for astronomers, especially in studying extremely violent interactions produced by black holes, neutron stars and dark energy. The problem with X-ray light is that it's hard to collect since most of the X-ray sources in the sky are very faint, not to mention that ground based observations in this spectrum are totally disabled by the fact that Earth's atmosphere is mostly opaque to X-ray.

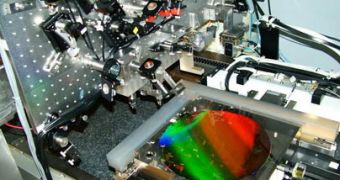

The solution lies in space telescopes equipped with mirrors capable of bending X-ray light, in order to collect and amplify it. Such a new device has been recently developed at MIT and may have applications in astronomy, biology and the semiconductor industry. On the nanoscale, the new X-ray mirror resembles a Venetian blind containing ultra smooth mirrors, called Critical-Angle Transmission gratings, embedded into a silicon structure. CATs may also prove to be a useful application in neutron optics, and for electron, atom and molecule diffraction.

The work was based on a previous invention made by Space Nanotechnology Laboratory researchers Ralf Heilmann and Mark Schattenburg, and was mostly made by graduate student Minseung Ahn of the Department of Mechanical Engineering from MIT.

One of the X-ray telescopes currently orbiting Earth is the now famous Chandra X-ray Observatory. However, NASA wants a new X-ray telescope, Constellation-X, which should have a power at least five times that of Chandra. Since the instruments of Chandra were built by the Space Nanotechnology Laboratory at MIT, NASA had good reasons to financially support the work did by Ahn.

According to MIT, the new X-ray mirror works extremely well when reflecting rays at shallow angles through the silicon substrate, while previous versions of mirrors used polyimide substrates, greatly reducing efficiency because this material absorbs X-rays very well. The reflective surfaces of the mirror are about 35 nanometers thin, are place in a parallel fashion in relation to each other and are separated by distances less than 150 nanometers.

"Imagine a thin, 40-foot-long, 8-foot-tall mirror, with surface roughness below a tenth of a millimeter. Then put tens of thousands of these mirrors next to each other, each spaced precisely an inch from the next. Now shrink the whole assembly - including the roughness - down by a factor of a million, and you have a good CAT grating", says Heilmann.

The prototype has already been tested at the Lawrence Berkeley National Laboratory, proving that the results are well within the theoretical predictions.

14 DAY TRIAL //

14 DAY TRIAL //