Single-walled and multi-layered carbon nanotubes have shown potential in the past due to their very attractive electrical properties and physical features; however, incorporating them into feasible integrated circuits is still a challenge because of difficulties in manipulating and positioning molecular size objects in order to achieve sufficient current outputs.

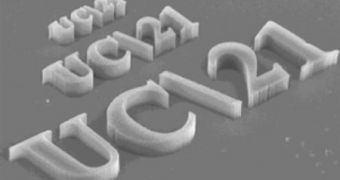

Now a new world record has been achieved by researchers at the University of Cincinnati, who developed a novel composite catalyst and optimal synthesis conditions for oriented growth of multi-wall CNT arrays, thus producing the longest aligned carbon nanotube arrays.

It took UC researchers Vesselin Shanov and Mark Schulz, co-directors of the University of Cincinnati Smart Materials Nanotechnology Laboratory, along with Yun YeoHeung and students, years of effort to invent the method for growing long nanotube arrays.

Employing this invention, the UC researchers (in conjunction with First Nano, a division of CVD Equipment Corporation of Ronkonkoma, New York) have produced extremely long CNT arrays (18 mm) on their EasyTube System using a Chemical Vapor Deposition (CVD) process.

Moreover, in a re-growth experiment on a separate substrate, they produced an 11-mm long CNT array. This array was then successfully peeled completely off the substrate. Without additional processing, the same substrate was reused for a successive growth that yielded an 8-mm-long CNT array.

"First, we were able to grow the arrays up to 18 mm," he says, ticking off the achievements. "Second, we produced a uniform carpet of 12-mm carbon nanotube arrays on a 4-inch wafer, which moves the invention into the field of scaled-up manufacturing for industrial application. Third, we filed a patent application on the inventions at the US Patent and Trademark Office and, fourth, we were invited to participate in a very prestigious workshop (invitation-only) organized by NASA and Rice University, where we presented our latest results. The workshop focused on Single Wall Carbon Nanotube Nucleation and Growth Mechanisms. This event was attended by the best scientists in the world working on synthesis carbon nanotubes, from Japan, China, Europe and the United States. Our presentation was accepted very well and confirmed that with the current record of 18-mm-long carbon nanotube arrays, and also with the big area growth on 4-inch wafers, we are leading in manufacturing extremely long CNT arrays."

The UC substrate for growing CNT arrays is a multilayered structure with a sophisticated design in which a metal based catalyst alloy is formed on top of an oxidized silicon wafer. Its manufacturing requires a "clean room" environment and thin-film deposition techniques that can be scaled up to produce commercial quantities. CNT synthesis is carried out in a hydrogen/hydrocarbon/water/argon environment at 750 degrees Celsius. The achievement of growing centimeter-long nanotube arrays provides hope that continuous growth of CNTs in the meter length range is possible.

Arranging nanotubes into arrays that can be transformed to plastic and other unusual substrates for applications such as flexible displays, structural health monitors and heads-up displays can enhance the performance of the devices built with conventional silicon-based technology.

14 DAY TRIAL //

14 DAY TRIAL //