When the idea of polymer circuits was introduced, designers and manufacturers were quite optimistic. Essentially plastics that carry current, the circuits were considered simple to make and shape, in addition to flexible, cheap and light.

Their manufacture proved, and continues to prove, much harder to pull off though, since existing techniques require the polymer to be in liquid form.

In order to paint circuits on a board, through inkjet printing or spraying techniques, the polymer needs to be in liquid form.

That means it need to be mixed with a solvent, and here is the problem: the solvent in question can end up dissolving more than it should, namely the layer below the circuit.

Polymers can also exhibit the coffee ring effect: polymers tend to concentrate at the edge of the droplet while drying.

The National Technical University of Athens figured it would be easier to bypass the need of solvents altogether rather than search for a different, safer one.

The result of their research is a laser printing technology that can print any 2D circuit without resorting to such chemicals.

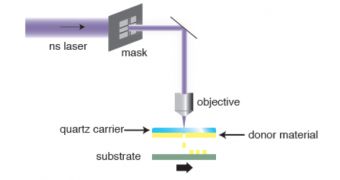

First off, a layer of the conducting polymer is spread on a sheet of glass or quartz, the so-called donor substrate.

Secondly, the receiving substrate is placed next to it, facing the layer of the polymer but not making any contact (a gap of a few micrometers is between them).

Finally, a laser is fired through the glass substrate and focused on the polymer layer. Through short bursts of energy, shock waves are created, which propel small amounts of the substrate on the receiving sheet of whatever material is used for the PCB.

Moving the donor substrate is all that it takes to give the circuits their shape. And since the polymer transfers as a solid, no solvents are needed.

The technique has been proven viable through a test where photovoltaic circuits of a conducting polymer called P3HT:PCBM were printed onto various substrates.

Biological sensing circuits (using a conducting polymer called polyaniline), have been printed as well. No longer will solvents interfere with or ruin biological measurements.

If the new technology catches on, technology in general should become more affordable, flexible and wearable. As for downsides, none are in sight. This looks every bit like a genuine technological milestone.

14 DAY TRIAL //

14 DAY TRIAL //