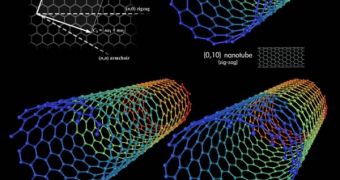

Though nanotube technology has been around for a while and it has been touted as one of the paths to significant future development in many fields, the question has always persisted of how the tiny components required to construct nanoscale devices would be handled.

When dealing with nanotubes several thousands of times thinner than a human hair, any excess pressure easily destroys them, even if they are several times more resistant than any other material at the same scale. Now, a European research initiative has finally managed to construct two very small robots, which can successfully handle nanotubes and arrange them into desired structures, ScienceDaily reports.

“The handling and characterization of these objects has become more and more important in materials science and nanotechnology. They have a huge application potential in various products,” University of Oldenburg expert Volkmar Eichhorn, who also holds an appointment at the associate OFFIS institute, explains. The EU has funded projects related to mastering carbon nanotube-handling technologies for some time, starting with the first ROBOSEM initiative.

That work yielded a few basic advancements, which were recently put at work in the new NanoHand project. Essentially, it focuses on learning how to use microrobts equipped with small and delicate nanotools, in order to handle rolls of carbon nanotube, only a few nanometers in diameter. The small machines are less than two centimeters in size, and operate inside the vacuum chamber of scanning electron microscopes, where their actions can be observed.

“The whole set-up is integrated into the vacuum chamber of the microscope. There is a glass plate where these mobile microrobots can walk around,” Eichhorn adds. The entire system makes use of the electrothermal principle, which relies on temperature differences for operation. Each of the machines is outfitted with small “jaws,” which open up to about two micrometers. They can handle objects as small as 100 nanometers in size. It is “really able to grip micro or even nano objects. We have handled objects down to tens of nanometres,” the expert adds.

“Worldwide, we are the first project that has really realized the automated microgripper-based pick-and-place experiments. The new thing is the high accuracy and the small scale of the objects – in the range of tens or hundreds of nanometers – and the excellent control and software architecture being built around this whole set-up facilitating a high degree of automation,” Eichhorn concludes.

14 DAY TRIAL //

14 DAY TRIAL //