Drivers could soon forget about the large costs associated with fixing their cars' paint jobs. A team of experts from Switzerland and the United States announces the creation of a self-healing polymer, that could be used to create paints which take care of themselves.

Members of the team imagine a future where drivers could simply shine ultraviolet (UV) light on the scratches on their car, and see the paint repair itself before their very eyes.

Alternatively, sensors that pick up scratches and UV light sources could be installed in car washes, taking care of small dents and imperfections as the vehicle is being cleaned. All of this may sound like fantasy, but the reality is that the technology is much closer to fruition than we believe.

In fact, the new discovery is detailed in a paper that appears in the April 21 issue of the top journal Nature. In it, experts describe how the new polymer-based material could make all of this a reality.

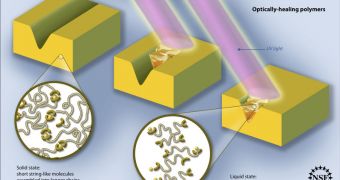

The main thing that makes metallo-supramolecular polymers so efficient is their ability to liquefy when subjected to UV light. They can fill in small dents and scratches, and then re-solidify when the light source is turned off.

US experts from the Case Western Reserve University and the Army Research Laboratory at Aberdeen Proving Ground worked together with Swiss colleagues at the University of Fribourg Adolphe Merkle Institute to develop the new material.

“This is ingenious and transformative materials research. It demonstrates the versatility and power of novel polymeric materials to address technological issues and serve society while creating broadly applicable scientific concepts,” says Andrew Lovinger.

The official is the director of the polymers program at the US National Science Foundation (NSF) Division of Materials Research. The DMR partially funded the new study.

In addition to automobiles, floors and furniture may also benefit from the new coatings, the team believes. Commercial consumer goods are primarily targeted by the new technology.

“These polymers have a Napoleon Complex. In reality they're pretty small but are designed to behave like they're big by taking advantage of specific weak molecular interactions,” says Stuart Rowan.

The expert, a professor of macromolecular engineering and science, and director of the Institute for Advanced Materials at CWRU, was the lead author of the Nature paper.

“Our study is really a fundamental research study. We tried to create materials that have a unique property matrix, that have unique functionality and that in principle could be very useful,” adds polymer chemistry and materials professor Christoph Weder, the director of AMI.

14 DAY TRIAL //

14 DAY TRIAL //