The race for advancing miniaturization capabilities in the electronics industry has been on for decades, and undoubtedly considerable progress has been made over the years. But a few years back, it became clear that a new method of constructing microprocessors and their transistors would have to be created, so the nanotechnology approach appeared. At the basis of this new method are nanowires, regular carbon or silicon wires, thousands of times thinner than a human hair. Now, European researchers have managed to produce a new technique for growing these wires, one that could again innovate the field.

One of the most immediate applications for the innovation is the production of smaller, faster, and more energy-efficient computer microchips. Applications in medicine and industrial development are also possible, analysts say. In fact, all these possible areas of advancement have been known for years, but the problem was that the science groups working on them did not have the means to produce large amounts of nanowires for their tests in affordable conditions and fast. At this point, nanowires, regardless of the materials they are made of, are hailed as the future electronics over the next decade.

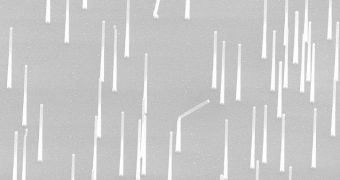

“Silicon technology becomes very challenging when you get down to 10-15nm. One of the problems of the [current] top-down approach is that it introduces harsh environments and you end up with devices that may be dominated by defects,” the coordinator of the European NODE project, Lars Samuelson, says. He is also the director of the Lund University Nanometer Structure Consortium. The NODE approach relies on growing the nanowires from a substrate, in a bottom-up approach that resembles growing crystals. “We call it ‘guided self-assembly,’ and it is a ‘bottom-up’ process that can result in fewer defects,” Samuelson reveals.

Even though their nanowires are vertical, they can contain various, alternating layers of materials. The research team learned how to control this aspect of their synthesis, by altering the properties of the substrate from which the nanotubes grew. “There are many potential opportunities for developing new technologies. This vertical arrangement may be the route to 3D circuit design as well as to realize monolithic on-chip optoelectronics,” the team leader adds. “This technology is not ready for industrial applications, and whether it will be three, six or nine years before it appears industrially, I cannot say. But we established the state of the art, we have the best results,” he concludes, quoted by AlphaGalileo.

14 DAY TRIAL //

14 DAY TRIAL //