The new developed material is known from previous experiments, but it has not been very effective; however, it has been discovered that porous structures inside the material greatly amplifies the shape changing effect, which could probably be used to construct new precision valves out of a cheap, lightweight material or pumps, without any mechanical moving parts.

The nickel-manganese-gallium alloy foam contracts in one direction and expands in the perpendicular direction of contraction, when subjected to an external magnetic field, and is able to retain the shape as the magnetic field is removed. It only regains its original shape when the magnetic field is applied once again, only this time it must be rotated by 90 degrees. The effect was called magnetic shape memory, and was first discovered in 1996.

On further study of the crystal lattice in the form of a parallelogram, it has been observed that it was able to lean and retain the shape towards a direction pointing to the left, whereas beyond a certain limit the crystal structure leaned to the right. This meant that every parallelogram structure had a magnetic moment, which when aligned to an external magnetic field switched leaning directions, to enforce the zigzag pattern along one alignment direction.

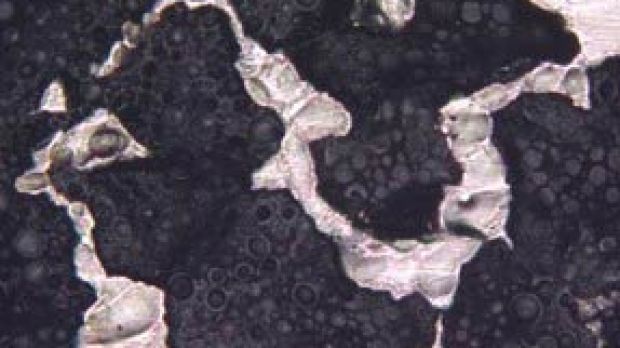

This double action elongates the crystals in the structure by 10 percent. However, the mass production of such a material is virtually and not commercially viable. So, David Dunand, of the Northwestern University of Illinois, decided to incorporate the crystalline alloy into polycrystalline structures, with boundaries oriented in a way that restricted the twin motion, resulting in very small strains. By doing so, they achieved a material with a strain increased over fifty times, through the introduction of pore with the help of a sodium aluminate salt, which was used as a support on which the alloy was pored; after this, they leached out the salt with the help of a acid.,

The resulting structure was exposed to a magnetic field of one Tesla, being rotated at a speed of 12,000 time per minute, as a laser carefully measured the strain in the structure, resulting in a poros material. This material included three quarters free space, and was able to sustain a deformation of over 0.12 percent under a magnetic field.

A strain inside the foam material could be as small as one hundred times the width of a single alloy crystal, and may have a reaction time of less than a millisecond, similar to the response time of the Terfenol D material, which works by a totally different principle and is much more expensive to make.

This advance in magnetic shape memories, could result in the creation of extremely small biomedical pumps, however its creators still study the possibility of using other materials with similar properties that could present even larger strain and smaller weight.

14 DAY TRIAL //

14 DAY TRIAL //