Despite their impressive sizes, modern planes are still fairly sensitive to mid-air impacts. Over the past year, a cascade of incidents has drawn attention to the fact that birds still remain a major hazard for continental or global flights, especially in terms of the damage they cause when they impact the fuselages. Maintenance work is currently difficult to perform on aircraft, because engineers have difficulties identifying the spots on the fuselage where the damage has been inflicted. But that will soon go away, as experts are already working on a new class of sensors to be incorporated directly into planes.

The detection devices will be built into the fuselage, and they will provide ground controllers, pilots and mechanics with a complete, real-time telemetry of a plane's condition. If any sort of damage occurs, warning lights will blink immediately, and decision-makers will have a lot more time to take action than they have had until now. Additionally, once the plane is on the ground, emergency response teams will be able to start working on the affected spot immediately, without having to perform a full plane check.

“We use thermoelectric generators, developed in cooperation with Micropelt GmbH, and adapt them so that they work efficiently,” Dr. Dirk Ebling, who is a research scientist at the Fraunhofer Institute for Physical Measurement Techniques IPM, in Freiburg, Germany, says. The consortium in charge of developing the new warning systems is led by EADS Innovation Works. According to specifications, the sensors must be light and self-sustaining, meaning there will be no cables or batteries running to and from them to the rest of the plane.

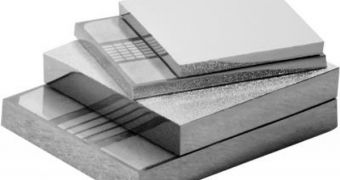

This type of traits will enable engineers to place the detectors in places that were unaccessible for this kind of devices before. The instruments draw their energy from the temperature differences between the fast-moving air outside, and the warm passenger cabin. On average, the temperature outside a normal jetliner is of -20 to -50 degrees Celsius, while the inside temperature is of about 20 degrees Celsius. The overall difference can reach as much as 70 degrees Celsius, the German experts report. The thermoelectric elements are powered by such differences, and they can transmit electricity to either the sensors, or to small radio devices able to relay the data to control centers or flight cabins.

The sensors could also be used in regular automobiles, eliminating the need for heavy cable assemblies. This would, in essence, reduce the weight of the vehicle, and make it more fuel-efficient, reducing its carbon footprint on the environment as well. The walls of old buildings could also be outfitted with such systems that could monitor the dampness levels. Medical shirts with thermoelectric elements could monitor patients' pulses as well, the team concludes.

14 DAY TRIAL //

14 DAY TRIAL //