Though only five years old, graphene is already one of the most promising materials in the entire world, mostly because of its peculiar chemical and physical properties. It is one of the strongest materials in the world, and can also conduct electrical current in a very strange way. But working with the material can be very difficult, as the one-atom-thick graphene is not exactly easy to spot. Now, scientists at the Northwestern University McCormick School of Engineering and Applied Science managed a success in the field, when they started using the dye fluorescein for observing graphene.

The dye has been in use for various applications for a very long time. For example, it is used to color the Chicago River green on St. Patrick's Day, or to find otherwise-invisible blood stains at a crime scene. But, recently, NU McCormick School Assistant Professor of Materials Science and Engineering Jiaxing Huang managed to find a way of using it to dye and evidence the thinnest material in the world, graphene. The work Huang conducted is detailed in the latest issue of the scientific Journal of the American Chemical Society (JACS).

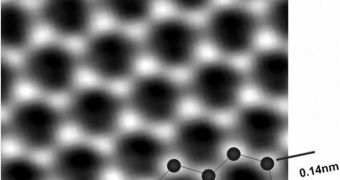

The most commonly used methods of detecting graphene at this point are atomic-force microscopy (AFM) and scanning electron microscopy (SEM). But both these methods are very time-consuming and expensive, and also have severe limitations. AFM, for example, can only be used to analyze small samples of the material on a smooth surface, whereas SEM imaging only works in a vacuum. Other viewing techniques, such as optical ones, are also very difficult to use on graphene, and require special types of substrates as well.

“There are really no good techniques that are general enough to meet the diverse imaging needs in the research and development of this group of new materials. For example, people have proposed putting graphene materials on plastic sheets for flexible electronics, but seeing them on plastic has been very challenging. If one cannot exam these materials, quality control is going to be difficult,” Huang says. “So we thought, how about we just put dye everywhere? That way, the whole background lights up, and wherever you have graphene will be dark. It's an inverse strategy that turns out to work beautifully.”

The samples that were dyed with fluorescein were then placed under a fluorescence microscope (FQM), which is easier and cheaper to use, and also readily available. The team was happy to observe that the clarity and resolution of the obtained images rivaled the same traits in AFM and SEM observations. “When (graduate student) Jaemyung first showed me the FQM images of graphene materials, I was tricked by the vivid details and thought they were SEM or AFM images. It's a simple and dirt-cheap method that works surprisingly well in many situations,” Huang concludes.

14 DAY TRIAL //

14 DAY TRIAL //