Crash tests are the ultimate tests to assess a vehicle's safety, but they are only the last to be run before a vehicle is approved for production. Oftentimes, the results of these tests are considerably different from the initial predictions, which are mostly run on computers. Now, experts from the Fraunhofer Institute have developed a new simulation process that is more accurate and conclusive with the final tests than ever before, AlphaGalileo reports.

The main focus of the research is the “B Pillar,” the structure that connects the floor and the roof of a vehicle. If a car, for instance, tumbles over, it's the job of this pillar to prevent the roof from deforming too much and crushing the passengers. There are specific demands from this structure – it has to be both lightweight, so as to minimize fuel consumption, but also remarkably strong, as only to deteriorate a little upon impact. Over the years, scientists and auto companies have been nearing this perfect material, and the new FI research provides even further momentum.

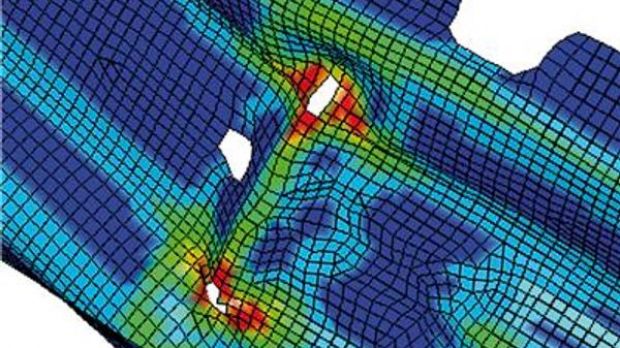

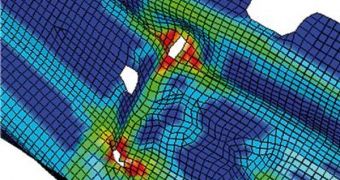

“We are well aware of the physical and mechanical characteristics of the materials in their original state. If you're going to fit these kinds of parts into vehicles, you need to take into account their deformation history during manufacture. With our failure model, we can simulate manufacturing processes more effectively,” Fraunhofer Institute for Mechanics of Materials IWM expert Dr. Dong-Zhi Sun, who has also been the leader of the research group that has worked on the new simulation, explains.

“To ensure we understand the manufacturing processes inside out, we work together closely with automakers and materials producers,” Sun adds. The technique he and his group developed allows auto manufacturers to understand the processes that affect the nature of the end-product, when it comes to some of the most critical parts of an automobile. “Unlike conventional crash simulations, we can predict far more accurately how extensively the component will deform during the crash before it fails,” Sun shares.

14 DAY TRIAL //

14 DAY TRIAL //