3D scanning is all well and good, but it's not as straightforward as it sounds. Even the ones that use a platform to spin things around need some time to build the 3D model, and most of the time, you need someone versed in CAD (computer-aided design) to smooth things over.

Not anymore though. At least not for the newest scanning solution that a long-time developer and manufacturer of portable 3D scanning technology has come up with.

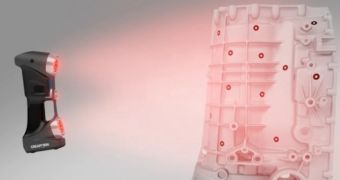

We didn't just call it a 3D scanner because there's some new software involved. The new Go!SCAN 3D scanner line needs help from the VXmodel program.

Basically, with this hardware-software combo, you can scan something and immediately send a file to be 3D printed. Or, well, almost immediately.

We admit that the few specialized 3D scanners used in 3D printing stores have something similar to this, but Creaform isn't looking at them.

Creaform is a unit of electronic instruments and electromechanical devices global manufacturer AMETEK Ultra Precision Technologies (which, in turn, is a division of AMETEK Inc.).

Instead, it wanted something portable, something you could use in the field and duplicate as soon as possible.

So you just use the Go!SCAN 3D white-light 3D scanner to make a CAD model of something, then use the VXmodel program to send it off, unless you want to make some quick finishes.

In the latter case, you can clean up meshes, make them capable of preventing water from seeping into the object, etc.

That way, the number of post-treatment steps is dramatically reduced and, by extension, the time between scanning and printing is cut to almost nil. Alignment, geometrical entities and cross-sections, mesh improvement and mesh editing is accomplished nearly automatically.

And before you ask, yes, the scanner doesn't just reproduce the physical shape, but also the colors. Funnily enough, this will be a waste in most situations, because there are very few full-color 3D printers in the world.

For those who want numbers, the scanning accuracy is of up to 0.1 mm (0.004 in.) and resolution of up to 0.2 mm (0.008 inches).

“Creaform’s unique Go!SCAN 3D and VXmodel module are the perfect complement for engineering and CAD professionals that use a 3D printer. The duo’s seamless and quick integration with any 3D printing or CAD process means that users no longer need to rely on third-party post-treatment software. This enables them to get the job done faster,” explained Francois Leclerc, Creaform’s product manager.

14 DAY TRIAL //

14 DAY TRIAL //