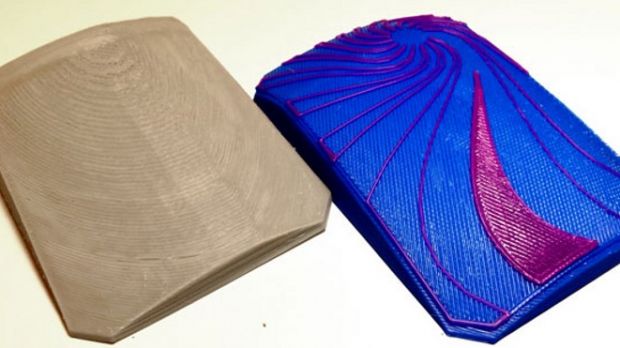

Stair-stepping is an effect that makes the edges of something look like it's made of jagged steps one over/next to another. It's a problem when you run a game in low resolution, and it's also a problem of low-end 3D printers. A new technique might have just eliminated the issue though.

Affordable 3D printers mostly use FDM (fused deposition modeling) technology to make something, which means that an extruder builds the figurine layer by layer.

If the resolution isn't good enough, however, the edges end up suffering from this stair-stepping effect, looking jagged.

Obviously, this isn't awesome. And polishing kind of defeats the purpose of having something 3D printed in the first place, and it's not like polishing and plastic do well together anyway.

Now, though, James Page and his crew at Topolabs have introduced a new algorithm that, according to them, will eliminate the problem.

How? By mimicking the way trees grow. Instead of going with the seemingly natural tendency of man to stack things on top of each other, he applied what he learned of forestry to create a new technology.

Well, technically, it's just a new way to direct the activity of 3D printers, but it's a significant change all the same.

How did it all start? With James' parents actually. His mother was a botanist and his father had a PhD in forestry.

Naturally, some interest crossed over to James. It's not like he could have lived his life without ever coming into contact with a cluster of trees, not with those sorts of parents.

Soon after he began to study 3D printing in 1995, he found similarities between FDM 3D printing and the textures found in timber.

Now, his startup company Topolabs offers a new software that helps a 3D printer emulate the patterns in wood, sinuous and sweeping being two of the epithets applied to them.

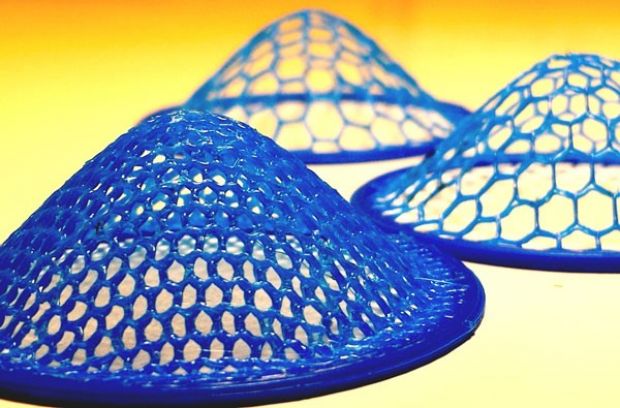

Based upon how a tree grows, the algorithm (or algorithms, since there are supposedly more of them) adds “transverse” fibers for additional support and “grows” the object instead of stacking tiny droplets of plastic (or whatever else) on top of one another.

The result is that the finished objects look much better and lack the jagged edges characteristic of items made with the same low-end 3D printers.

The Topolabs parts use a material grain that follows the shape of the parts, eliminating the structural weakness of totally flat layers. The ultimate goal is to allow low-cost 3D printers to be used in real-time, full quality manufacturing.

14 DAY TRIAL //

14 DAY TRIAL //