According to a new scientific paper published in the March 9 issue of the top journal Science, a new type of polymer is perfectly capable of creating 3D structures, once it's submerged in water. The material originally comes as sheets, its developers say.

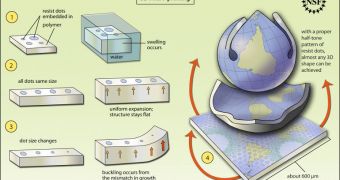

University of Massachusetts Amherst (UMA) investigators say that they were able to make the polymer sheets come together in various 3D shapes by simply placing dots on the surface of the material, at specifically-designated intervals.

If a line of dots is straight, and all of the grooves are of the same diameter, then the polymer simply expands, without experiencing any type of lateral distortion. On the other hand, if the size of the dots changes within the initial sheet, then the inflated version of the polymer would buckle.

This curbing effect occurs due to the fact that various portions of the polymer do not grow in similar manners when exposed to water. The research team that created this amazing approach was led by UMA scientists Christian Santangelo and Ryan Hayward.

Working together with several of their colleagues, the specialists were able to put together a technique for printing the polymer sheets, which uses basic polymer science and photographic techniques.

The number and implications of potential applications are staggering, say researchers from the US National Science Foundation (NSF), who supported this study via a Faculty Early Career Development and Materials Research Science and Engineering Centers award.

The polymer sheets may be used to advance the field of robotics, but also to create new drug delivery systems. The latter would be able to allow the survival of a drug molecule in the human bloodstream long enough for the polymer transport vessel to reach the targeted tissue, and release its cargo.

“This paper reports an interesting fusion of experimental technique and theory to develop an innovative method for making self-actuating materials that will assume a desired three-dimensional shape,” NSF Division of Materials Research program director, Daryl Hess, explains.

What is very interesting about the technique used to produce the new polymer is that it enables the material to suffer no deformations when exposed to water, if ultraviolet light is shone on it simultaneously.

14 DAY TRIAL //

14 DAY TRIAL //