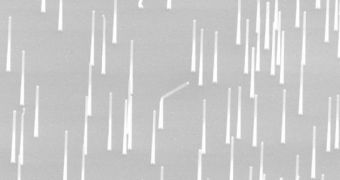

At this point, there's no doubt in the minds of engineers that nanowires are the building material of the future, suited to construct everything from next-generation computer chips to the ominous space elevator to orbit. Still, before these goals become a reality, there are some painstaking details to work out, such as how to grow these tubes to enormous lengths, while at the same time making sure that they do not get entangled or bent in the process.

In themselves, the wires are extremely small, only a few nanometers (billionths of a millimeter) in thickness, and therefore highly susceptible to any outside influence. While they are very resistant for something their size, they still need to be cared for until more can be grouped together.

In order to make all the new and exciting properties of nanowires available for research throughout the world, to incorporate in new technologies, the composition of the materials themselves needs to be thoroughly analyzed. The purpose of this investigation is to learn exactly how the synthesis conditions in which the wires grow affect their later development.

“If we can understand the origin of the electrical properties of nanowires, and if we can rationally control the conductivity, then we can specify how a nanowire will perform in any type of device. This fundamental scientific understanding establishes a basis for engineering,” Northwestern University (NU) McCormick School of Engineering and Applied Sciences Assistant Professor Lincoln Lauhon explains. The expert has also been the lead author of a paper detailing the new observational techniques, published in the March 29th online issue of the scientific journal Nature Nanotechnology.

Using an investigation tool known as atom probe tomography (APT), Lauhon has managed to observe the levels of dopants, small impurities that gather among the carbon nuclei, inside nanowires with diameters between 3 and 100 nanometers. By understanding how these amounts of dopants have come to be in the wires, researchers could potentially create much more productive synthesis methods for each class of carbon nanowires in particular.

“We simply mapped where all the atoms were in a single nanowire, and from the map we determined where the dopant atoms were. The more dopant atoms you have, the higher the conductivity. We would like to establish the general principles for doping semiconductor nanowires,” Lauhon concludes.

14 DAY TRIAL //

14 DAY TRIAL //