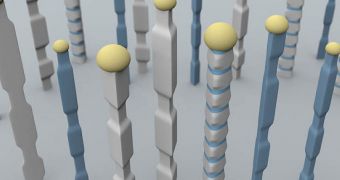

Scientists at the Massachusetts Institute of Technology (MIT), in Cambridge, say they are now capable of controlling a large number of the most important parameters guiding the growth of nanotubes. These materials are heavily researched today, due to their huge potential.

Many believe that nanowires will open the door to a host of new technologies, as well as improve on existing designs. New, extremely sensitive sensors could be produced from these materials. Light-emitting diode (LED) technologies could also be substantially improved.

However, until recently, scientists could only produce nanowires, but had little to no control on some of the new structures' basic properties, such as their composition, or their width. Both these parameters can now be controlled by changing the amount of gases used during production.

While this may not seem that important at first, it actually represents a huge step forward for scientists. Now that the properties of these nanoscale structures can be controlled, it will become possible to put together materials that are especially designed for extremely specialized applications.

The new study was led by MIT assistant professor of materials science and engineering, Silvija Gradečak. Together with her team, the expert explored ways in which nanowires could be fashioned into better sensors.

One of the reasons why these tiny structures are so efficient at detecting chemicals is that they have a very large surface area, when compared to their volume. Being able to control how the nanowires look like will enable the team to improve on these natural performances even further.

Details of the new research appear in a paper published in the latest issue of the journal Nano Letters.

The MIT group worked with indium nitride and indium gallium nitride, but they say that their approach to controlling nanowire properties can also be used on production processes involving other elements.

Nanowires are usually grown from so-called seed particles. The properties of the seed determine both the composition and the dimensions of the wires, so influencing the primary structure is all it takes to change the properties of the resulting product.

“We’re able to control both of these properties simultaneously,” the team leader explains.

14 DAY TRIAL //

14 DAY TRIAL //