A group of investigators at the Rice University, in the United States, announces the development of a new manufacturing technique, that allows them to “amplify” the production of carbon nanotubes. The innovation will play a critical role in developing efficient electric grids in the near future.

According to the team, this is an important breakthrough in this field of research, which seeks to develop materials that can be made available in raw amounts to replace the current, copper-based grid that most countries are operating.

At this point, armchair quantum wires (AQW) show the most promise. They are made up of metallic nanotubes that are weaved together in a manner that allows them to carry current with nearly zero loss over large distances.

Copper tends to lose some of the electricity it carries as heat. This phenomenon contributes in part to the low efficiency level standard power grids operate at. AQW therefore provide an ideal option for a replacement material.

Study author Andrew R. Barron, the Charles W. Duncan Jr.-Welch rofessor of chemistry at Rice, and a professor of materials science at the university, says that copper wires tend to lose electricity at a rate of 5 percent for every 100 miles traveled.

In a paper published in the latest issue of the esteemed American Chemical Society journal Nano Letters, the expert says that the main difficulty with producing AQW in sufficiently large amounts to enable practical applications was the fact that it could not be manufactured in bulk.

Standard production technologies formed this type of material alongside numerous other flavors of nanowires, and separating them from each other proved to be a very costly and difficult process.

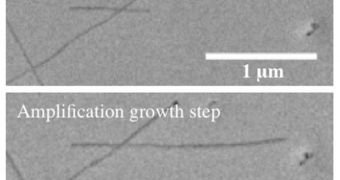

Barron and his team moved past this limitation by developing a production method in which small batches of individual nanotubes are separated from other chemicals, and then forced to grow longer.

This is achieved by attaching an iron/cobalt catalyst to the ends of nanotubes, and then tweaking the conditions of the environment in which the tubes grow. In the end, this leads to the AQW being “amplified,” as the team calls the process.

The new investigation was made possible by fund provided by the Robert A. Welch Foundation and the US Air Force Office of Scientific Research.

14 DAY TRIAL //

14 DAY TRIAL //