Investigators at the Rensselaer Polytechnic Institute (RPI) announce the development of a new type of nanoscale-engineered battery, that is capable of accumulating energy about 40 times faster than today's top lithium-ion batteries.

This remarkable power density was made possible by the latest advancements in nanotechnology engineering, which the RPI team incorporated in the new design. An advanced nanoscale material was also used to underlie this ability.

The next generation of high-power, rechargeable Li-ion batteries for electric cars could be right around the corner, thanks to the new power-storage device, the RPI team believes. The battery could be a good temporary measure to promote the use of electrical vehicles, until efficient fuel cells are produced.

Hydrogen is undoubtedly the way of the future, but efficient technologies to use the chemical in fuel cells are still a few years away. Until then, high-efficiency Li-ion batteries such as the RPI one could fill in the vacancy.

In addition to car batteries, the new devices could also be used to power up portable devices, such as tablets, laptops, cell phones and mp3 players, the group behind the innovation believes.

“Charging my laptop or cell phone in a few minutes, rather than an hour, sounds pretty good to me,” says RPI Department of Mechanical, Aerospace and Nuclear Engineering professor Nikhil Koratkar.

“By using our nanoscoops as the anode architecture for Li-ion rechargeable batteries, this is a very real prospect,” the expert goes on to say. He was the leader of the research group that developed the material.

“Moreover, this technology could potentially be ramped up to suit the demanding needs of batteries for electric automobiles,” Koratkar adds. The scientist explains that the nanoscoop material is what made the new batteries possible.

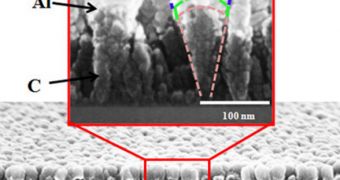

The material's shape reminds experts for a cone featuring a scoop of ice cream on top. The design, shape and structure of the nanoscale material makes it capable of withstanding extremely high rates of electrical charge and discharge.

In regular Li-ion batteries, such a high rate of transfer would cause the electrodes to deteriorate and rapidly fail, but this phenomenon is prevented in the nanoscoops by the materials' very structure.

The RPI team published details of its achievement in a paper called “Functionally Strain-Graded Nanoscoops for High Power Li-Ion Battery Anodes,” which will be published in an upcoming issue of the esteemed scientific journal Nano Letters.

“Due to their nanoscale size, our nanoscoops can soak and release Li at high rates far more effectively than the macroscale anodes used in today’s Li-ion batteries,” Koratkar says.

“This means our nanoscoop may be the solution to a critical problem facing auto companies and other battery manufacturers – how can you increase the power density of a battery while still keeping the energy density high?” he concludes.

Funds for this research were provided by the US National Science Foundation (NSF) and the New York State Energy Research and Development Authority (NYSERDA).

14 DAY TRIAL //

14 DAY TRIAL //