In an accomplishment that might herald the future of electronics, researchers at the Cornell University in the United States were able to create large arrays of nanoscale resonators using the carbon compound graphene, currently one of the most researched materials in the world.

The work was prompted by the fact that microscopic machines are now used in a large variety of electronic devices. They can be found in printheads, display pixel switches and motion sensors, to name only a few of the devices containing them.

But what the industry wants to do is reduce the dimension of these machines to the nanoscale. This could enable the creation of extremely sensitive sensors, incredibly fast switches, as well as very precise accelerometers, to name but a few potential applications.

Difficulties in doing so arise from the peculiar nature of very small objects, which begin being governed by the laws of quantum mechanics, rather than Newtonian physics. Limitations in production technologies are also keeping the field steady.

In their new investigation, researchers at the Cornell University took an important step forward when they manged to shrink these electromechanical machines down to the nanoscale.

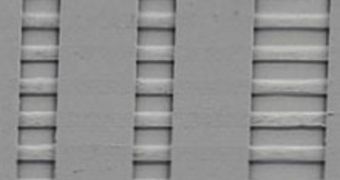

They were able to use the carbon compound graphene to create very tiny resonators, organized in large arrays. Graphene is considered to be the most promising material for creating the nanoelectromechanical systems (NEMS) of the future.

The substance is the most electrically-conductive chemical out there, a lot more so than copper. It is also stronger than any other material science knows of.

Graphene is also bi-dimensional, as it is only one-atom thick. This enables it to have amazing chemical and physical properties. Paul McEuen, a Cornell physics professor, managed to use these traits for creating nanodevices.

The equipment used in the production process was developed from existing tools, that are regularly used to etch silicon chips on flat wafers. McEuen led the research with fellow Cornell professor Harold Craighea, Technology Review reports.

“We're making large numbers of identical resonators, which demonstrates a transition from a lab experiment to a technology,” McEuen says of the new accomplishment.

“The two major obstacles in implementing nanodevices are scale-up and reproducibility in performance,” adds University of California in Berkeley (UCB) physics professor Alex Zettl

“Using single-layer graphene allows many devices to be made in one shot, with similar performance,” the expert, who is also involved in constructing similar devices at UCI, concludes.

14 DAY TRIAL //

14 DAY TRIAL //