All progress begins with a small step, and while we can't say that manufacturing things in outer space is at its onset, it hasn't gone that far beyond the initial stage either. The biggest hurdle may as well have just been overcome though.

Back in September, you might remember that we chronicled the voyage into outer space of the first space-worthy 3D printer.

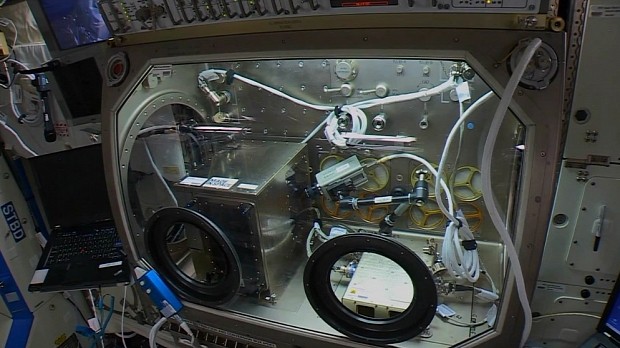

A company called Made in Space created the first 3D printer capable of operating in zero gravity. Then NASA loaded it into a shuttle and sent it out into the cosmos.

Although it was never meant to go that far. Instead, it docked with the International Space Station, where it has been under examination since.

The preliminary revision stage has finally passed, however, which means that 3D printing can finally begin in Earth's orbit.

The first object has been 3D printed in outer space

The crew of the International Space Station, ISS for short, have used the Made in Space 3D Printer to create a tiny faceplate that identified the printer maker.

Not such an amazing object at all, but one which has big implications in the grand scheme of things. After all, it marks the beginning of orbital manufacture.

Which is to say, it proves that humankind is more or less ready to start manufacturing things in outer space. It will take years, decades or even centuries before we can craft space ships and stations, but at least the science has been figured out.

It's not all symbolic, however. The printing of the faceplate also provided important feedback about how 3D printing works in microgravity. This info will help NASA and Made in Space create better and larger printers as the years pass.

What the printing process revealed

The objects stick better to the print tray than they do on Earth, for one thing. NASA was even able to determine that it might be possible to bind plastic layers differently in orbit than on Earth.

And with microgravity having no ill effects on the printed objects, that means that things like medical implements, tableware and puzzles will be just as safe to make as little plastic patches for whatever dents the ISS gathers over the years.

True, real space manufacturing won't happen until Made in Space or someone else approved by NASA creates a larger 3D printer capable of working in those conditions. But the model currently up there will be invaluable in the new one's development, and may even see new space stations created with such facilities integrated into the blueprints from the very start.

14 DAY TRIAL //

14 DAY TRIAL //