When Micron announced that it has turned to the 20nm fabrication process for manufacturing its next-gen NAND Flash memory, many in the industry have feared that the smaller production node will lead to a decrease in endurance, but Micron has recently put these worries to rest when it said that 20nm Flash will be just as reliable as 25nm memory.

Traditionally, when Flash manufacturers turns to a more advanced node for the production of their NAND memory, this is accompanied by a decrease in endurance.

This is what happened when the industry moved from 35nm to 25nm, and this is what many expected to happen with the transition to the 20nm node.

However, these reliability issues were on Micron’s agenda for the move to 20nm, so the outfit has taken the decision to use the high-k metal gate (HKMG) technology in the fabrication of the chips, which is generally reserved for building devices such as microprocessors or graphics cores.

"We think [HKMG] is the right answer. [...] Do we see any long-term issues associated with the reliability of the device? Absolutely not! We think that this is the right way to scale from 25nm to 20nm,” said Ronald Foster, chief financial officer at Micron, during conference call with financial analysts.

“And we probably got few tricks up our sleeves to move on beyond that," continued the company’s rep, who was cited by the Xbit Labs website.

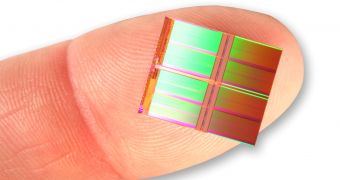

Earlier this month, Micron, together with its partner Intel, have announced that they have started mass production of 64Gb NAND memory chips built using the 20nm node.

The chips, which entered test production in April of this year, are built by IMFT (Intel Micron Flash Technologies) in their fab in Lehi, Utah, and are destined to be used in next-gen Solid State Drives, tablets, smartphones, as well as in other devices.

14 DAY TRIAL //

14 DAY TRIAL //