Nanotags coating the cartridges used by a vast range of firearms could be made out of a combination of pollen and grit, to make the identification of the person firing the weapon much more accurate, say UK researchers. This way the tag would not only be invisible, but it would also have a unique signature and could be specially designed to attach itself to a number of materials, including gloves, clothing and even the skin of the person handling the cartridge.

Even after being fired, the case and the bullet of the cartridge would still contain the unique signature of the tag. The identification technique is relatively similar to an already existing method used by the authorities to link people to crimes, involving the comparison of explosive residue left on the gun with possible signatures of propellant found on the suspect's clothing, for example.

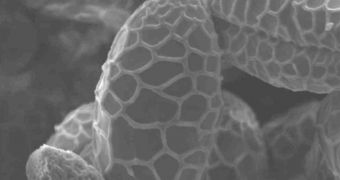

"We decided to work with pollens because they have a unique structure, resistant to temperature and easily recognizable. It's also easily dispersed and carried around in clothes, skin, etc.," said leader of the study Paul Sermon of the University of Surrey. The tag actually contains not only pollen, but also a mix of crystal oxides such as zirconia, silica and titanium oxide. And since the concentrations of different materials used to make the nanotag can be easily varied, large numbers of unique tags can be made.

Additionally, pollen grains vary according to the type of plant species, further enhancing the number of identification markers. "The most challenging part of the project was nanoengineering a coating robust enough to withstand the high temperatures of firing and that would still release the tags when touched," Sermon said.

The nanotags could be added to existing cartridges through the current manufacturing processes, and may find their way onto the market in as little as one year.

Sermon says that the team is currently working to develop a means to retain DNA samples on the cartridge, for even more accurate identification procedures. This could be done by coating the cartridge with a special type of grit that traps skin cells and protects them from the heat released by the propellant during firing. The same technique could be used on knives, to make them able to retain and protect DNA.

14 DAY TRIAL //

14 DAY TRIAL //