I think it is pretty obvious that the petrol alone will not be sufficient enough to satisfy our energy needs in the near future. Thus, the scientists are permanently looking for alternative fuels and energy production devices. Natural gas is just one of the alternatives. Now you are probably wondering why we are not using it to power our cars, since its is highly efficient and produces far less pollution during the burning process. To store natural gas basically means that we have to liquefy it.

However, liquefying a gas is not sufficient to store it efficiently, it would also need to be refrigerated in order to maintain a low pressure inside the container. On the other hand, refrigeration systems require extra power to be inserted, which is a highly inefficient technique, not to mention that such storing devices are also too expensive for mass production. Storing natural gas at normal atmospheric temperatures is mostly dangerous due to the high pressures exerted on the walls of the container that pose high risks of explosion.

In order to eliminate the unwanted pressure, scientists developed microporous materials which are used to absorb gas inside them. This basically means that the material could store the same volume of gas, but at lower pressures. The U.S. Department of Energy is just one of the leading designers in sponge-like materials with high methane storing capabilities.

According to a newly published paper, DOE succeeded in developing a material that could store up to three time more methane than the previous record holder. Hong-Cai Zhou, one of the authors of the study, draws attention to the problems related to storing natural gas, which prevent the methane-powered vehicles to be as efficient as their petrol counterparts.

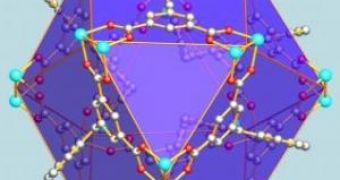

Called MOF, or metal-organic framework, the new crystalline material has a surface area far higher than that of any other gas absorbing material previously designed, making it ideal for creating compounds for fuel storing applications. MOF is actually a nanostructure, known as PCN-14 with a surface area of about 2000 square meters per gram of substance, 28 percent higher than the outcome predicted by the DOE.

14 DAY TRIAL //

14 DAY TRIAL //