A long time ago, metallurgists noticed that certain solid metals, which had been engineered for ductility, could suddenly become brittle. The process, designated liquid metal embrittlement (LME), has been under investigation ever since. Now, a team of scientists finally proposes an explanation.

LME oftentimes occurs suddenly. This can have significant consequences on systems using ductile metals, since they can literally crack and give way without any type of warning. In the construction industry, this can result in the death of many workers.

Before this study was released, others investigators were able to discover that certain liquid metal impurities may play a role in LME, but the extent of the progress in finding an answer stopped there.

The much-awaited breakthrough came from a team of ceramic researchers from the Leigh University, who were lead by professor of materials science and engineering Martin Harmer. He is also the director of the Center for Advanced Materials and Nanotechnology at the university.

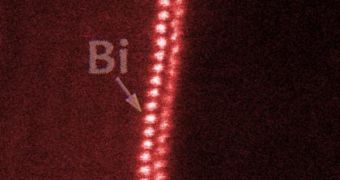

This group was the first to produce atomic-scale images of the grain boundaries, or internal interfaces, where LME first occurs. Their datasets provide unprecedented resolution into the processes that conspire to trigger catastrophic failures in these materials.

Harmer explains that his group was also the first-ever to observe a bilayer grain boundary phase transition as it occurred. He adds that one of the ways to prevent LME from occurring is to develop ways of strengthening the chemical bonds that exist between materials in grain boundaries.

“This is a very exciting discovery. It gives us a much clearer understanding of the atomic mechanism of LME and it promises to improve our ability to control and fine-tune the properties of metals and other materials during fabrication,” the team leader explains.

The paper detailing the findings, called “The Role of a Bilayer Interfacial Phase on Liquid Metal Embrittlement,” appears in the September 23 issue of the top journal Science. Experts from the Clemson University and the Lehigh Nanocharacterization Laboratory were also a part of the study.

“A bilayer had been seen before in a ceramic system, but no one had seen such examples of bi- and trilayers in metals. There is a very strong bond between bismuth and nickel, so it had never been clear why the alloy is prone to embrittlement,” Harmer explains.

“But the bonds between bismuth atoms are weak. We are the first group to see the formation of a bismuth bilayer that weakens this material,” he concludes.

14 DAY TRIAL //

14 DAY TRIAL //