3D printing technology usually has to figure out how to use certain, existing materials in manufacturing projects, but the new one invented by German scientists was used to create a new material.

Scientists at the Karlsruhe Institute of Technology in Germany were able to develop a 3D printing process that made a new material that is both lighter and stronger than steel.

PhD student Jens Bauer and his colleagues were able to invent a 3D printing process that created microscopic structures less dense than water but stronger than steel.

That means that the strength-to-weight ratio of the material is among the highest ever encountered, if not the highest.

We can already imagine the material being used in the aerospace industry, and any other fields where lightweight, sturdy materials are necessary.

And all this because 3D printing can create unique geometries that increase the usefulness of certain substances.

It's a really big slap to the face of the Ashby chart, which shows that the higher a pressure resistance goes over 280 MPa (megaPascals, often used to measure stiffness or tensile strength), the denser the material is.

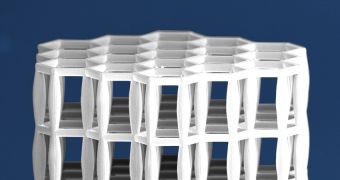

Only wood and bone are exceptions and, now, there is a third: 3D printed microscopic trusses out of a ceramic material, as shown in the photo up on the left, and the video embedded below.

Bauer and his colleagues have also coated the ceramic in aluminum oxide, through atomic layer deposition (ALD).

The strongest structure they were able to create was lighter than 1000 kilos per cubic meter and capable of withstanding pressures of up to 280 MPa, despite the honeycomb shape and alumina coating being of just 50 nanometers in thickness. That's where the “lighter than water, stronger than steel” description comes from.

Sadly, the Nanoscribe laser lithography system used to achieve this feat can only make objects that are tens of micrometers in size. Hopefully, larger ones will become possible in the future.

14 DAY TRIAL //

14 DAY TRIAL //